|

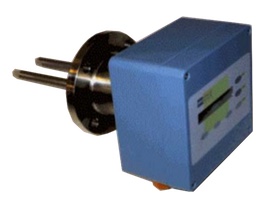

| TECO HK Series Microwave Consistency Transmitters |

Typically less than half of the cost of other microwave transmitters, the HK series microwave transmitters will measure the percentage of total solids of additives in water and percentage of moisture in wood chips with the same transmitter. Applications include measurement and control of machine, recycle & broke stock, measurement and control of % totals solids of starch additives, measurement and control of % solids (limestone, kaolin clay) in coatings.

- Low cost – typically less than half the cost of other microwave transmitters

- Easy to install

- One point calibration

- Adjustable antenna units to maximize sensitivity to process conditions

- Internally compensated for temperature

- No routine maintenance required. Install & forget!

- Current and Digital Outputs

- Contact closure

- Versatile – Same transmitter can be used in Pipes, tanks, chests, belts & chutes.

- Paper and Board Mills:

- Machine Stock Consistency Measurement and Control

- Broke Consistency Measurement and Control

- Paper Mills

- Bleaching State Feed Consistency

- Consistency Measurement & Control in Fiber Lines with changing Wood Species

- Production Measurment at Integrated Mills

- Mechanical Pulp Plants

- Refiner Consistency

- All Fiber Line Consistency Measurments and Control

- De-inking Pulp Plants

- Consistency and Control of Deinking Pulp

- Production Measurement of Deinking Pulp