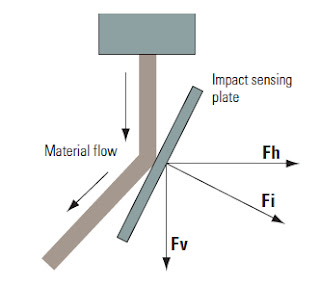

Impact weighers are designed so that the impact plate can only move horizontally. This means that from the total impact force “Fi,” only the horizontal component “Fh” is measured. In the diagram above, “Fv” is ignored. This guarantees that changes in the weight of the sensing plate, due to material build-up or sensing plate wear, will not affect the zero or accuracy of the system.

|

| Impact Weighers components (Thermo Scientific Ramsey) |

- Easy installation in difficult process environments

- Measurement is not affected by changing the impact point on the sensing plate • Build-up on the sensing plate cannot influence the zero point

- High reliability and low maintenance

- Mechanical damping system absorbs shocks and damps vibration

- Sensor allows some overload withoutdamage to the system

- Sensor is located in a dust-tight enclosureexternal to the process stream

- Operates accurately in pulsating or surging flows

To learn more, download the Ramsey DE10 and DE20 Impact Weigher brochure here. For more information, contact TECO by visiting https://teco-inc.com or by calling 800-528-8997.