|

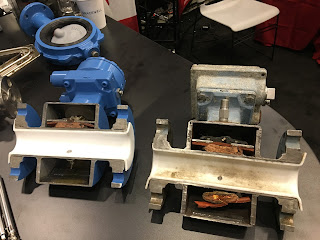

| Cutaways of electromagnetic flow meters - one removed from service (right) and one remanufactured (left). |

Electromagnetic flow metering is based on the principles of Michael Faraday's 1832 discovery. When a conductive liquid, such as water, is moved through a magnetic field a voltage is induced in the liquid at right angles to the magnetic field. The size of the voltage is directly proportional to the volume flow rate. This induced voltage is detected by sensors known as electrodes. These electrodes transfer the voltage signal to the processing electronics where it can be converted into a usable industrial standard signal.

It's important that the flow meter tube is non-magnetic, and austenitic stainless steel is the most commonly used material. It's also essential that the flow meter tube has a lining that electrically insulates it from the liquid inside, and provides a non-reactive barrier with any corrosive liquids being measured. Distinguishing between flow induced voltage changes, electrochemical noise, and plant induced noise, is a barrier to accurate electromagnetic flow metering. This can be particularly difficult in dirty and industrial applications. The choice of electromagnetic flowmeters with advanced noise suppression can mitigate unwanted noise and provide extremely high orders of accuracy as a result.

To ensure that your electromagnetic flow meters will be optimized for safety, longevity, and performance, the advice of a qualified flow instrumentation expert should be sought out. That expert will be able to help you with the best selection of the appropriate flow device for your specific application, be it electromagnetic flow meters or another flow technology.