Providing educational information on flowmeters, industrial control, process instrumentation, valves, and valve automation. Posts include interesting and unique industrial control applications, new product information, and ways of improving efficiency and saving money through proper maintenance, repair, service, and re-manufacturing.

Courtesy of Thompson Equipment Company | TECO-INC.COM | (504) 833-6381

Magnetic Flow Meters with Specialized Construction Still the Best Bet for Dredging Applications

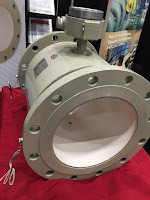

Electromagnetic flow meters commonly measure slurry mixture flow on cutter suction dredgers and trailing suction hopper dredgers. These type of flow meters use exposed electrodes and non-conductive flow tubes. Ordinary magnetic flow meter flow tubes are not designed to withstand the abrasive conditions prevalent in dredging. Standard magnetic flow meter electrodes are prone to wear, breakage, and polarization requiring frequent re-adjustment. Standard electrode seals may also deteriorate and cause leaks and false readings.

As an alternative, non-invasive (non-wetted) flow meters, such as clamp-on or Doppler ultrasonic flow meters, have long been proposed because of their ease of installation and maintenance savings. However, testing of clamp-on or Doppler ultrasonic flow meters has never panned out in dredging applications. While there has been limited success on smaller sized diameters, there are few, if any, large diameter dredging pipe application success stories.

As an alternative, non-invasive (non-wetted) flow meters, such as clamp-on or Doppler ultrasonic flow meters, have long been proposed because of their ease of installation and maintenance savings. However, testing of clamp-on or Doppler ultrasonic flow meters has never panned out in dredging applications. While there has been limited success on smaller sized diameters, there are few, if any, large diameter dredging pipe application success stories.

Dredging engineers always seek the simplest and most accurate method of measuring slurry flow. Considering this, there is convincing evidence that the use of customized electromagnetic flow meters, specifically designed to stand up to the rigors of dredging, look to be the best overall option.

Dredging-specific flow meters provide wear solutions that can extend the life of equipment and keep systems at maximum operational levels. Some users report life span up to 10 years.

The dredging modifications include custom engineered ceramic brick or polyurethane liners, 3/4" stainless steel inlet and outlet protectors, independently sealed electrode wells, and field accessible Hastelloy B electrodes.

Thompson Equipment (TECO), a manufacturer of severe service magnetic flow meters located in New Orleans, will "remanufacture" any make or model of electromagnetic flow meter for dredging service. They have decades of experience servicing and remanufacturing instrumentation, and are leaders in building severe service flow meters.

Electromagnetic flow meters have always been appealing for dredging applications in terms of accuracy, resolution, and response time. Their performance problems, caused by the direct and continuous flow of abrasive slurries, are mitigated through specialized construction. By applying electromagnetic flow meters specifically designed for the application, dredging engineers now achieve excellent reliability, long life and significant reduction in maintenance and operational costs.

As an alternative, non-invasive (non-wetted) flow meters, such as clamp-on or Doppler ultrasonic flow meters, have long been proposed because of their ease of installation and maintenance savings. However, testing of clamp-on or Doppler ultrasonic flow meters has never panned out in dredging applications. While there has been limited success on smaller sized diameters, there are few, if any, large diameter dredging pipe application success stories.

As an alternative, non-invasive (non-wetted) flow meters, such as clamp-on or Doppler ultrasonic flow meters, have long been proposed because of their ease of installation and maintenance savings. However, testing of clamp-on or Doppler ultrasonic flow meters has never panned out in dredging applications. While there has been limited success on smaller sized diameters, there are few, if any, large diameter dredging pipe application success stories.Dredging engineers always seek the simplest and most accurate method of measuring slurry flow. Considering this, there is convincing evidence that the use of customized electromagnetic flow meters, specifically designed to stand up to the rigors of dredging, look to be the best overall option.

|

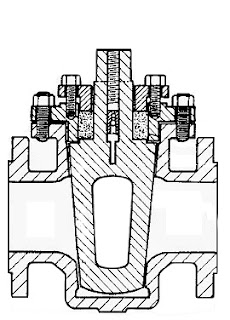

| Dredging flow meter. (TECO) |

The dredging modifications include custom engineered ceramic brick or polyurethane liners, 3/4" stainless steel inlet and outlet protectors, independently sealed electrode wells, and field accessible Hastelloy B electrodes.

Thompson Equipment (TECO), a manufacturer of severe service magnetic flow meters located in New Orleans, will "remanufacture" any make or model of electromagnetic flow meter for dredging service. They have decades of experience servicing and remanufacturing instrumentation, and are leaders in building severe service flow meters.

Electromagnetic flow meters have always been appealing for dredging applications in terms of accuracy, resolution, and response time. Their performance problems, caused by the direct and continuous flow of abrasive slurries, are mitigated through specialized construction. By applying electromagnetic flow meters specifically designed for the application, dredging engineers now achieve excellent reliability, long life and significant reduction in maintenance and operational costs.

Selecting the Proper Flow Meter: Other Considerations

You Get What You Pay For

Engineers and maintenance personnel who purchase flow meters should remember that accurate instruments cost more based on their features and capabilities. It is always better to search for the type of flow meter best suited to a specific application before sacrificing features in favor of lower cost.

Flow meter specifiers should also take the time to examine long-term ownership costs. It may turn out that flow meters with low purchase prices may be very expensive to maintain. On the other hand, a flow meter with a high purchase price may require little or no service, and therefore lower cost of ownership over time. Lower purchase prices do not always represent the best long term, installed value.

Know Your Process

Users need to closely evaluate their overall process conditions, which include flow rates, pressure and temperature, and operating ranges. Be cautious of lower priced alternatives whose operating parameters don't fully support the requirements of the application.

All flow meters are affected to some extent by the process media and the way they are installed. As a result, their real-time performance will often be different from the controlled reference conditions under which they calibrated. There are some general rules that can be applied to flow meters to assist in reducing uncertainty:

The need for recalibration of flow meters is generally a function of how well the instrument is paired to its particular application. Should the application be critical, the flow meter accuracy should be checked at frequent, regular intervals. In some instances, mostly non-critical applications, recalibration may not be necessary for a period of years, becuase the application operating parameters never change.

Keep in mind though, that no matter what flow meter technology is chosen, overall system accuracy can never exceed the accuracy of the equipment used to perform the flow meter calibration. With that said, the most precise flow calibration systems on the market employ a positive displacement design. This type of calibrator, directly traceable to the National Institute of Standards and Technology (NIST) via water draw validation, provides total accuracy of at least 0.05 percent.

For more information on flow meter selection, installation, calibration, service, and replacement contact Thompson Equipment Company (TECO). Call them at 800-528-8997 or visit their web site at https://teco-inc.com.

Engineers and maintenance personnel who purchase flow meters should remember that accurate instruments cost more based on their features and capabilities. It is always better to search for the type of flow meter best suited to a specific application before sacrificing features in favor of lower cost.

Flow meter specifiers should also take the time to examine long-term ownership costs. It may turn out that flow meters with low purchase prices may be very expensive to maintain. On the other hand, a flow meter with a high purchase price may require little or no service, and therefore lower cost of ownership over time. Lower purchase prices do not always represent the best long term, installed value.

Know Your Process

Users need to closely evaluate their overall process conditions, which include flow rates, pressure and temperature, and operating ranges. Be cautious of lower priced alternatives whose operating parameters don't fully support the requirements of the application.

All flow meters are affected to some extent by the process media and the way they are installed. As a result, their real-time performance will often be different from the controlled reference conditions under which they calibrated. There are some general rules that can be applied to flow meters to assist in reducing uncertainty:

- For the lowest uncertainty of measurement, positive displacement meters are generally the best option.

- Electromagnetic meters provide for the widest flow range and turbine meters are usually the best choice for the highest short-term repeatability.

- Despite their high initial cost, Coriolis meters are ideal for measuring particularly viscous substances and anywhere that the measurement of mass rather than volume is required.

- In general, flow meters with few or no moving parts require less time and attention than more complex flow meters.

- Meters constructed with multiple moving parts may malfunction because of dirt, grit or grime present in the process fluid.

- Flow meters with impulse lines can also plug or corrode.

- Flow meters with flow dividers and pipe bends sometimes suffer from abrasive media wear and blockages.

- Swings in ambient temperature may affect the internal dimensions of the flow meter and could require temperature compensation.

The need for recalibration of flow meters is generally a function of how well the instrument is paired to its particular application. Should the application be critical, the flow meter accuracy should be checked at frequent, regular intervals. In some instances, mostly non-critical applications, recalibration may not be necessary for a period of years, becuase the application operating parameters never change.

Keep in mind though, that no matter what flow meter technology is chosen, overall system accuracy can never exceed the accuracy of the equipment used to perform the flow meter calibration. With that said, the most precise flow calibration systems on the market employ a positive displacement design. This type of calibrator, directly traceable to the National Institute of Standards and Technology (NIST) via water draw validation, provides total accuracy of at least 0.05 percent.

For more information on flow meter selection, installation, calibration, service, and replacement contact Thompson Equipment Company (TECO). Call them at 800-528-8997 or visit their web site at https://teco-inc.com.

TECO Valve Repair Services

TECO repairs control valves, manual valves, relief valves, actuators, and valve instrumentation. Expert, certified technicians are available to repair or recondition your valve and actuator to like-new condition.

For more information, call 800-528-8997 of visit the TECO web site at https://teco-inc.com.

Download the PDF here.

For more information, call 800-528-8997 of visit the TECO web site at https://teco-inc.com.

Download the PDF here.

Thompson Equipment is a National Stocking Distributor for ABB Rotameters (Variable Area Flowmeters)

VA Master FAM540 - The armored VA meter is ideal for the chemical, pharmaceutical and food industries.

Armored purgemeter FAM3200 - Suitable for most low flow, high pressure and corrosive applications in municipal and industrial settings.

PurgeMaster 10A6100 - Ideal for many low flow rate applications, such as purging control lines and instrument enclosures.

VA Master glass tube meters - Used for a wide variety of liquids and gases in most industrial processing facilities.

TECO (Thompson Equipment Co.) Your National Stocking Distributor

800-528-8997

NIST Traceability

Calibration means the comparison and adjustment (if necessary) of an instrument’s response to a stimulus of precisely known quantity, to ensure operational accuracy. In order to perform a calibration, one must be reasonably sure that the physical quantity used to stimulate the instrument is accurate in itself. For example, if I try calibrating a pressure gauge to read accurately at an applied pressure of 200 PSI, I must be reasonably sure that the pressure I am using to stimulate the gauge is actually 200 PSI. If it is not 200 PSI, then all I am doing is adjusting the pressure gauge to register 200 PSI when in fact it is sensing something different.

Ultimately, this is a philosophical question of epistemology: how do we know what is true? There are no easy answers here, but teams of scientists and engineers known as metrologists devote their professional lives to the study of calibration standards to ensure we have access to the best approximation of “truth” for our calibration purposes. Metrology is the science of measurement, and the central repository of expertise on this science within the United States of America is the National Institute of Standards and Technology, or the NIST (formerly known as the National Bureau of Standards, or NBS ).

Experts at the NIST work to ensure we have means of tracing measurement accuracy back to intrinsic standards, which are quantities inherently fixed (as far as anyone knows). The vibrational frequency of an isolated cesium atom when stimulated by radio energy, for example, is an intrinsic standard used for the measurement of time (forming the basis of the so-called atomic clock). So far as anyone knows, this frequency is fixed in nature and cannot vary: each and every isolated cesium atom has the exact same resonant frequency. The distance traveled in a vacuum by 1650763.73 wavelengths of light emitted by an excited krypton-86 (86Kr) atom is the intrinsic standard for one meter of length. Again, so far as anyone knows, this distance is fixed in nature and cannot vary. This means any suitably equipped laboratory in the world should be able to build their own intrinsic standards to reproduce the exact same quantities based on the same (universal) physical constants. The accuracy of an intrinsic standard is ultimately a function of nature rather than a characteristic of the device. Intrinsic standards therefore serve as absolute references which we may calibrate certain instruments against.

The machinery necessary to replicate intrinsic standards for practical use is quite expensive and usually delicate. This means the average metrologist (let alone the average industrial instrument technician) simply will never have access to one. While the concept of an intrinsic standard is tantalizing in its promise of ultimate accuracy and repeatability, it is simply beyond the reach of most laboratories to maintain.

In order for these intrinsic standards to be useful within the industrial world, we use them to calibrate other instruments, which are then used to calibrate other instruments, and so on until we arrive at the instrument we intend to calibrate for field service in a process. So long as this “chain” of instruments is calibrated against each other regularly enough to ensure good accuracy at the end-point, we may calibrate our field instruments with confidence. The documented confidence is known as NIST traceability: that the accuracy of the field instrument we calibrate is ultimately ensured by a trail of documentation leading to intrinsic standards maintained by the NIST. This “paper trail” proves to anyone interested that the accuracy of our calibrated field instruments is of the highest pedigree.

Thompson Equipment Company's calibration lab is ISO/IEC 17025 Accredited and NIST traceable.

Ultimately, this is a philosophical question of epistemology: how do we know what is true? There are no easy answers here, but teams of scientists and engineers known as metrologists devote their professional lives to the study of calibration standards to ensure we have access to the best approximation of “truth” for our calibration purposes. Metrology is the science of measurement, and the central repository of expertise on this science within the United States of America is the National Institute of Standards and Technology, or the NIST (formerly known as the National Bureau of Standards, or NBS ).

Experts at the NIST work to ensure we have means of tracing measurement accuracy back to intrinsic standards, which are quantities inherently fixed (as far as anyone knows). The vibrational frequency of an isolated cesium atom when stimulated by radio energy, for example, is an intrinsic standard used for the measurement of time (forming the basis of the so-called atomic clock). So far as anyone knows, this frequency is fixed in nature and cannot vary: each and every isolated cesium atom has the exact same resonant frequency. The distance traveled in a vacuum by 1650763.73 wavelengths of light emitted by an excited krypton-86 (86Kr) atom is the intrinsic standard for one meter of length. Again, so far as anyone knows, this distance is fixed in nature and cannot vary. This means any suitably equipped laboratory in the world should be able to build their own intrinsic standards to reproduce the exact same quantities based on the same (universal) physical constants. The accuracy of an intrinsic standard is ultimately a function of nature rather than a characteristic of the device. Intrinsic standards therefore serve as absolute references which we may calibrate certain instruments against.

The machinery necessary to replicate intrinsic standards for practical use is quite expensive and usually delicate. This means the average metrologist (let alone the average industrial instrument technician) simply will never have access to one. While the concept of an intrinsic standard is tantalizing in its promise of ultimate accuracy and repeatability, it is simply beyond the reach of most laboratories to maintain.

In order for these intrinsic standards to be useful within the industrial world, we use them to calibrate other instruments, which are then used to calibrate other instruments, and so on until we arrive at the instrument we intend to calibrate for field service in a process. So long as this “chain” of instruments is calibrated against each other regularly enough to ensure good accuracy at the end-point, we may calibrate our field instruments with confidence. The documented confidence is known as NIST traceability: that the accuracy of the field instrument we calibrate is ultimately ensured by a trail of documentation leading to intrinsic standards maintained by the NIST. This “paper trail” proves to anyone interested that the accuracy of our calibrated field instruments is of the highest pedigree.

Thompson Equipment Company's calibration lab is ISO/IEC 17025 Accredited and NIST traceable.

Reprinted from "Lessons In Industrial Instrumentation" by Tony R. Kuphaldt – under the terms and conditions of the Creative Commons Attribution 4.0 International Public License.

Magnetic Flowmeters for Measuring the Frac Fluid

A piece of equipment used in hydraulic fracturing is the blender truck. It contains the equipment used to prepare and measure the "frac fluid". Frac fluid is composed of water, sand, specialty chemicals, and gels, and is highly erosive and sometimes corrosive. This "blended" mixture of sand, water and chemicals is then injected into a well to hydraulically open cracks in the rock layers below. By opening the cracks, trapped natural gas and petroleum is released and flows more freely.

Magnetic flowmeters are employed to measure the frac fluid flow and volume. These flowmeters must accurately meter the frac fluid into the well, stand up to the continual erosive media, and be durable enough to handle the harsh ambient conditions. Standard process magmeters experience shortened lifespans under these conditions and must be pulled from service and repaired. A better alternative is a severe service flowmeters designed specifically for this service.

Thompson Equipment Company (TECO) manufactures an electromagnetic flowmeter (magmeter) designed for frac fluid flow metering. The TECO design incorporates two significant features to improve performance and extend operating life:

Thompson Equipment Company (TECO) manufactures an electromagnetic flowmeter (magmeter) designed for frac fluid flow metering. The TECO design incorporates two significant features to improve performance and extend operating life:

- A ceramic sleeved liner made of “magnesia partially stabilized zirconia”

- The use of solid tungsten electrodes.

TECO Proudly Supports Sky High at the Midland Permian Basin Banquet & Clay Shoot

Thompson Equipment Company (TECO) proudly supports the fantastic work Sky High does "Saving Kids. Healing Families."

Sky High's mission is to provide comfort, fund research and save lives of children fighting pediatric cancer and other life-threatening conditions at Texas Children’s Cancer Center, St. Jude Children’s Research Hospital and the Ronald McDonald House of Memphis.

TECO is proud to attend and support the "Midland Permian Basin Banquet & Clay Shoot" this past September. We strongly suggest our friends, vendors, and partners get involved with this wonderful group.

https://teco-inc.com

800-528-8997

Electromagnetic Flow Meters for Accurate Measurement of Flowing Conductive Fluids and Slurries

|

| Magnetic Flow Meter (Badger Meter) |

Electromagnetic flow meters employ Faraday’s law of electromagnetic induction, whereby voltage is induced when a conductor moves through a magnetic field. The liquid acts as the conductor, with energized coils outside the flow tube creating the magnetic field. The produced voltage is directly proportional to the flow rate. Magnetic flow meter technology is not affected by temperature, pressure, or density of the subject fluid.

Electromagnetic flow meters tend to be heavy in larger sizes and may be prohibitively expensive for some purposes. However, irrespective of price and size, there are multiple reasons why magnetic flow meters are the instrument of choice for certain applications. They are resistant to corrosion and their ability to accurately measure dirty fluids makes them very suitable for wastewater measurement. As mentioned, there are no moving parts in a magnetic flow meter, keeping maintenance to a minimum. Power requirements are also low. Electromagnetic flow meters are available in a wide range of configurations, sizes, and construction materials to accommodate various process installation

requirements.

|

| Severe service flow meter. (TECO) |

Contact Thompson Equipment Company (TECO) with any magnetic flow meter requirement. Their decades of applying, repairing, re-manufacturing, and designing magnetic flow meters will assure a successful implementation.

Choosing the Right Industrial Flow Meter

|

| Which Industrial Flow Meter to Choose? |

This white paper, courtesy of Badger Meter, does a great job outlining all the various types of flow meter technologies, including:

- Coriolis

- Differential Pressure

- Electromagnetic

- Positive Displacement

- Thermal Mass

- Turbine

- Impeller

- Variable Area

- Ultrasonic

- Vortex

- Oval Gear

- Nutating Disc

https://teco-inc.com

800-528-8997 for Immediate Service

Metal Cone Variable Area Flowmeters

|

| Metal Cone Variable Area Flowmeters (ABB) |

Overview

Metal cone variable area flowmeters are indispensable where high pressure and / or high temperature operating conditions exist. The stainless steel primaries as well as the PTFE liner primaries are proven in many applications even under hardest conditions.

Design options include:

- Flanged connections.

- Hygienic design.

- PTFE-liner for aggressive fluids.

- Steam jacket for temperature sensitive fluids.

All metal cone variable area flowmeters are available as an analog indicator with or without alarms, as well as 4 to 20 mA electronic transmitter with HART communication, NAMUR contact outputs, and optionally with a graphical display. Metal cone variable area flowmeters can be used in all hazardous areas.

More information about metal cone variable area flowmeters can be found in the embedded document below, or you may download the ABB Variable Area Flowmeter brochure directly from this link.

Thompson Equipment Company

https://teco-inc.com

800-528-8997

More information about metal cone variable area flowmeters can be found in the embedded document below, or you may download the ABB Variable Area Flowmeter brochure directly from this link.

Thompson Equipment Company

https://teco-inc.com

800-528-8997

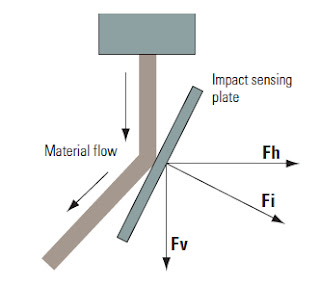

Impact Weighers - Principle of Operation

Impact weighers are in-line instruments used for weighing of bulk materials. They are designed to measure the force generated by the impact of flowing material on a sensing plate. This force creates a mechanical deflection as it impacts the plate. This deflection is measured by a sensor and converted into an electrical signal. That signal is then processed by an electronic controller, which displays the flow rate and total weight.

Advantages:

Impact weighers are designed so that the impact plate can only move horizontally. This means that from the total impact force “Fi,” only the horizontal component “Fh” is measured. In the diagram above, “Fv” is ignored. This guarantees that changes in the weight of the sensing plate, due to material build-up or sensing plate wear, will not affect the zero or accuracy of the system.

|

| Impact Weighers components (Thermo Scientific Ramsey) |

- Easy installation in difficult process environments

- Measurement is not affected by changing the impact point on the sensing plate • Build-up on the sensing plate cannot influence the zero point

- High reliability and low maintenance

- Mechanical damping system absorbs shocks and damps vibration

- Sensor allows some overload withoutdamage to the system

- Sensor is located in a dust-tight enclosureexternal to the process stream

- Operates accurately in pulsating or surging flows

To learn more, download the Ramsey DE10 and DE20 Impact Weigher brochure here. For more information, contact TECO by visiting https://teco-inc.com or by calling 800-528-8997.

Thank You To Our Customers - A TECO Crawfish Boil

TECO occasionally hosts crawfish boils at our customers' facilities. We think this is a great way to say thanks and to do something a little out of the ordinary for them. It gives everyone an opportunity to get to know each other, tell a good story and maybe have a laugh or two - all around some really great food.

Thompson Equipment Company

Flow Meter Remanufacturing, Custom Flow Solutions, Full Service Repair, Calibration, and Valve Automation Center. http://www.teco-inc.com | 800-528-8997

New Smart Valve Sensor Provides Preventive Maintenance Diagnostics on Quarter-Turn Valves

|

| The ifm MVQ101 Smart Valve Monitor |

https://teco-inc.com

800-528-8997

Remanufactured Process Instruments Save You Money, Resources and Time

TECO is the world's largest remanufacturer of magnetic flow meters, instrumentation and valves. Their secret is the combination of experience, trained technicians and facilities. TECO can remanufacture virtually any process instrument or valve. Every remanufactured item meets or exceeds the original OEM specifications and performance standards.

Send TECO your worn-out flowmeters, instruments and valves and get them back as good as new (or better)!

Severe Service Flowmeters by TECO

For flow measurement of extremely abrasive slurries in Mining, Dredging, Fracing, and Oil and Gas Exploration.

Capabilities include:

Capabilities include:

- Liners: magnesia stabilized zirconia ceramic, aluminum oxide ceramic, polyurethane rubber, neoprene rubber, Linatex, Teflon (PTFE), rotationally molded Tefzel (ETFE), PFA, and others.

- Electrodes: SS, Hastelloy C (C-276), Hastelloy B, zirconium, titanium, platinum/iridium, solid tungsten carbide, tungsten carbide coating, etc.

- Exotic tube constructions available (100% titanium).

- Specialty Coatings: epoxy paints, powder coat, custom colors, etc.

800-528-8997

Happy 4th of July from Thompson Equipment Company

"The United States is the only country with a known birthday. All the rest began, they know not when, and grew into power, they know not how.... There is no "Republican," no "Democrat," on the Fourth of July, — all are Americans."

James Gillespie Blaine

ABB Rotameter (Variable Area Flow Meter) Application Notes

The Variable Area Flowmeter is an instrument for measuring the flow of liquids and gases in pipelines. It includes a vertical tube through which the fluid flows whose diameter increases from the bottom to the top and a float which can move vertically in the tube.

The Variable Area Flowmeter is an instrument for measuring the flow of liquids and gases in pipelines. It includes a vertical tube through which the fluid flows whose diameter increases from the bottom to the top and a float which can move vertically in the tube.As the flow increases this float moves to a higher position until its resistance to the fluid flow is balanced by the float’s buoyed weight in the fluid, a value which is constant and independent of the flowrate. The position of the float is a measure of the flowrate. The flowrate values can be read on a scale.

Here is a listing of applications where rotameters (variable area flow meters) are commonly used and links to where their PDF documents can be downloaded.

- Variable Area Flow Meters for Tank Purging Applications

- Variable Area Flow Meters for Gas Analyzers Applications

- Variable Area Flow Meters for Plant Potable Water Flow Monitoring

- Variable Area Flow Meters for Plant Gaseuous Fuel Monitoring

- Variable Area Flow Meters for Air Leakage Testing

- Variable Area Flow Meters for Alarms

- Variable Area Flow Meters for Bubble Tube Purge Level Measurement

- Variable Area Flow Meters for Continuous Forced Lubrication of Bearings

- Variable Area Flow Meters for Cooling Water to Protect Heat Generating Equipment

- Variable Area Flow Meters for Laboratory Measurements

- Variable Area Flow Meters for Hot Water Chill Water Flow Balancing in Large Buildings

Important Flowmeter Performance Metrics

|

| Animation of differential flow |

performance metrics include accuracy, precision/repeatability, turndown ratio, resolution, ease of installation, straight pipe run requirements, on-going operations and maintenance, and costs.

Accuracy

Accuracy is the difference between a measured value and the actual value. No flowmeter is 100% accurate and most manufacturers provide a range of accuracies in their product line - tighter accuracy requirements are typically more expensive and may also be more restrictive to specific applications.

Precision/Repeatability

The precision or repeatability of a measurement entails the ability to reproduce the same value (e.g., flow rate) with multiple measurements of the same parameter, under the same conditions.

Turndown Ratio

|

| Rotameter (ABB) |

Resolution

The resolution is the smallest increment of flow that can be incrementally registered by the meter. For example, a water meter designed for a small diameter pipe may be able to provide a resolution of 100 pulses per gallon (or more) as a signal output, but a meter designed for a larger pipe or higher maximum flow may only be able to provide 1 pulse per 100 gallons. Further, a very large flow meter may only be able to provide 1 pulse per 1000 gallons. The metering system may have limitations with regard to peak signal frequency or minimum time between pulses to properly register the data signal.

Ease of Installation

Select make-and-model decisions considering size and weight constraints, specific electrical and communications needs, and the overall environment the flowmeter will operate in.

|

| Magnetic flowmeter (TECO) |

Applicable to some types of fluid (gas, liquid and steam) flowmeters, straight-pipe run requirements relate to the length of unobstructed straight pipe required leading up to and immediately following the flow meter’s location. Obstructions in the fluid flow (such as elbows, tees, filters, valves, and sensor fittings) cause changes in the flow pattern (flow regime and velocity profile). Straight-pipe runs allow the flow pattern to normalize/stabilize making measurements by velocity-type and differential-pressure-type flow meters less prone to measurement error. Straight-pipe run requirements are usually expressed in terms of the number of pipe diameters.

The straight pipe requirement is in addition to the length of the flowmeter itself. The straight-pipe run requirements can be reduced with the addition of flow straightening or flow conditioning devices installed upstream.

Ongoing Operations and Maintenance

|

| Vortex flowmeter (ABB) |

Installation Versus Capital Cost

In some situations, the cost to install a flowmeter can be greater than the capital cost; this can be true where system shutdowns are necessary for flowmeter installations, or where significant redesign efforts are needed to accommodate a flowmeter’s physical size, weight, or required connection. In these cases, decision makers should consider alternative technologies that may have a higher capital cost but a much lower installed cost. A good example of this is the use of non-intrusive flow metering technologies (e.g., ultrasonic flowmeters) that typically have a high capital cost but often a significantly reduced installed cost. It is recommended that meters be installed with isolation valves or switches making it easier to remove, replace, or service the meter in the future.

Reprinted and abstracted from US Department of Energy paper titled "Metering Best Practices: A Guide to Achieving Utility Resource Efficiency, "

Severe Service Magmeters for Fracing Operations

Proven in the heat of a West Texas summer, and the cold of an Alberta winter, this TECO magmeter is designed from the ground up to withstand corrosive slurries, acids, bases and solvents.

|

| Severe Application Meter (TECO) |

Calling upon sixty-plus years experience in magmeter application, failure analysis, repair, and design, TECO developed several innovative magmeter features intended to improve longevity in fracing operations.

|

| FRAC Trucks |

Second, TECO developed electrodes built from a solid tungsten carbide billet, which afford unparalleled wear resistance. Given the sand density in the frac fluid, noise reduction is critically important; so, the tungsten carbide is polished leaving a hard, smooth finish that significantly reduces noise in the electrode circuit.

|

| Erosive sand tears up other magmeters. |

|

| Internal view of SAM after 500,000,000 pounds of sand flowed though the core. Upon inspection, the customer found the flow tube to be looking “brand new”. |

Download the PDF version of this article here.

Contact TECO by visiting https://teco-inc.com of call 800-528-8997 for more information.

Oval Gear Flow Meters: Accurate, Robust, and Long Life

Although there are many types of flow meters used to measure fluid flow rates, positive displacement (PD) designs, including Oval Gear flow meters, are unique as they are the only meters on the market that directly measure actual volume. All other metering techniques infer the volume by making a type of measurement and equating it to the flow rate.

Although there are many types of flow meters used to measure fluid flow rates, positive displacement (PD) designs, including Oval Gear flow meters, are unique as they are the only meters on the market that directly measure actual volume. All other metering techniques infer the volume by making a type of measurement and equating it to the flow rate.One of the key criteria in selecting the right flow meter is the degree of accuracy dictated by the application. To meet high-precision requirements in various industrial environments, Oval Gear flow meters fit the bill. These meters feature a wide flow range, low pressure drop and extended viscosity range. Oval Gear flow meters offer easy installation and high accuracy, plus measure high temperature, viscous and caustic liquids with simple calibration.

Oval gear flow meters are simple and robust. They operate by interlocking two oval gears, offset by 90 degrees, inside the meter housing which are then rotated by the flowing media. They are very rugged and designed to operate in very harsh environments. Accuracy is maintained irrespective of temperature, viscosity change, or flow pulsation. It's not unusual to see these meters perform in the field for upwards of 40 years.

|

| Flow path and operation of Oval Gear Flow Meter |

Oval Gear flow meters are an excellent choice for any number of industrial applications including:

- Chemicals

- Petrochemicals

- Water and Wastewater

- Oils and Diesel Fuel

- Pulp and Paper

- Paints and Coatings

- Printing

For more information on Oval Gear flow meters visit https://teco-inc.com or call 800-528-8997.

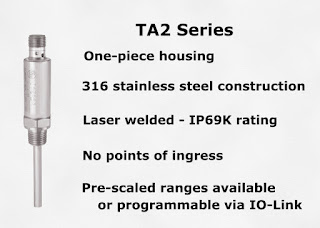

Compact and Ultrafast Response Temperature Transmitters: The IFM TA2

Traditional temperature sensors are constructed from multiple components, assembled and calibrated together. The assembly and calibration of the components is time consuming and requires a high level of skill. These temperature instrument assemblies, due to their open design, are susceptible to moisture, corrosion and other environmental conditions which are a major cause for instrument stress. Furthermore, periodic maintenance for verification of calibration is needed, adding costs that directly affect profitability.

Traditional temperature sensors are constructed from multiple components, assembled and calibrated together. The assembly and calibration of the components is time consuming and requires a high level of skill. These temperature instrument assemblies, due to their open design, are susceptible to moisture, corrosion and other environmental conditions which are a major cause for instrument stress. Furthermore, periodic maintenance for verification of calibration is needed, adding costs that directly affect profitability.IFM's innovative TA2 temperature instrument solves this problem. Constructed of 316 stainless steel, this fully laser welded, one piece hermetically sealed instrument is rated IP69K. There are no points of ingress to cause drift or damage the sensor and they are fully calibrated during manufacture and ready to use right out of the box. The sensor is pre-scaled in various popular ranges and fully scaleable to custom ranges using the IO-Link communication and programming tool.

With a compact 3-1/4" diameter and 1-1/2" long housing, the TA2 installs into the tightest locations. A bright led located in the M12 connector gives visible indication that the sensor is operational. Wiring is conventional 2-wire loop power for easy installation.

The IFM TA2 transmitter line is available both with standard threaded process connections for standard applications, and the popular sanitary process connection, for applications in the food and beverage industries.

Finally, the TA2 temperature transmitters dramatically reduce response time. The standard fast response unit can react to 50% of the temperature change in less than 1.0 second, and just 3.0 seconds to 90%, while the ultrafast versions react in just 0.5 seconds and 1.0 seconds, respectively.

For more information on the IFM TA2, call TECO at 800-528-8997 or visit https://teco-inc.com.

Failed Flowmeter - Replace with New or Remanufactured?

Many companies don't realize that when you have a failed mag meter or mass meter, it's often more cost-effective and efficient to have them restored to mint condition, than it is to replace them with new units.

But if you send meters to the original manufacturer they can disappear into their system for weeks or months. And you have no idea how long it will really take, or if it will fail again later from undetected problems. The fact is you can't afford the loss of productivity or downtime. But what if there were a place you could send broken flow meters that could save you money and time by restoring them to pristine condition. A cost-effective specialist who could guarantee rapid turn around time and premium customer service. A team of experienced professionals with the capabilities to keep equipment in service, even if it's no longer supported by others.

For a proven partner like this, there's only TECO. Established in 1947, TECO has become the global leader in restoration and customization of magnetic flow meters, Coriolis meters, and other process control instruments.

TECO understands that time is money, which is why they provide the fastest turnaround time in the

industry. They don't simply repair a broken part and return it, they do a full restoration and back the whole meter with a full warranty. Their quality control includes NIST traceable flow calibration, which is often required by regulatory agencies, and ISO 9000 standards. They also provide independent calibration to serve your preventive maintenance and metrology needs.

While their low cost, high quality work has made them the industry leader, it's their commitment to premium customer service that keeps their clients loyal. Extensive capabilities, combined with a focus on service, also means they can manufacture custom flow meter solutions to meet the demands of severe applications.

If you have failed mag meters, Coriolis meters, or other instruments, call TECO today. After receiving your equipment they'll turn around a quote in 48 hours or less - no return authorization required. To develop a customized solution for your needs, contact TECO.

Phone (504) 833-6381

Visit https://teco-inc.com

But if you send meters to the original manufacturer they can disappear into their system for weeks or months. And you have no idea how long it will really take, or if it will fail again later from undetected problems. The fact is you can't afford the loss of productivity or downtime. But what if there were a place you could send broken flow meters that could save you money and time by restoring them to pristine condition. A cost-effective specialist who could guarantee rapid turn around time and premium customer service. A team of experienced professionals with the capabilities to keep equipment in service, even if it's no longer supported by others.

For a proven partner like this, there's only TECO. Established in 1947, TECO has become the global leader in restoration and customization of magnetic flow meters, Coriolis meters, and other process control instruments.

TECO understands that time is money, which is why they provide the fastest turnaround time in the

industry. They don't simply repair a broken part and return it, they do a full restoration and back the whole meter with a full warranty. Their quality control includes NIST traceable flow calibration, which is often required by regulatory agencies, and ISO 9000 standards. They also provide independent calibration to serve your preventive maintenance and metrology needs.

While their low cost, high quality work has made them the industry leader, it's their commitment to premium customer service that keeps their clients loyal. Extensive capabilities, combined with a focus on service, also means they can manufacture custom flow meter solutions to meet the demands of severe applications.

- Low cost, rapid restoration of mag meters, mass meters and other instruments.

- Pristine, like-new equipment, backed with a full warranty.

- Customized solutions and expert customer service you can trust.

If you have failed mag meters, Coriolis meters, or other instruments, call TECO today. After receiving your equipment they'll turn around a quote in 48 hours or less - no return authorization required. To develop a customized solution for your needs, contact TECO.

Phone (504) 833-6381

Visit https://teco-inc.com

Top 5 Reasons TECO Consistency Transmitters Stand Above the Competition

- TECO Consistency Transmitters are shipped with built-in flow-rate compensation. This is important because blade style consistency sensors are sensitive to shifts in production flow-rate. This means that their output has a component which is strictly a function of flow-rate. If this isn’t compensated for, changes in flow-rate will look like changes in consistency. TECO Consistency Transmitters include a flow-rate input so that this flow-rate function which automatically gets applied to the consistency signal. This feature is unique to TECO.

- The key feature of our C3000 and C5000 probe style sensors is that they aren't sensitive to flow-rate changes to begin with. The C3000 and C5000 are insensitive to shifts in production flow-rate below 3.0 fps. This means that as long as the flow-rate stays below 3.0 fps, shifts in flow-rate will not produce any negligible affect on the probe output signal. For flow-rates above 3.0 fps when using C3/5000 series sensors, it is recommended that active compensation be used.

- The C5000 sensor is retractable, allowing it to be removed from an active process. This feature is particularly useful when installed in hostile measurement environments, such as blow lines and bleach plant operations. The retractable feature allows for quick change-out when it comes time for replacement, allowing the restoration of a critical measurement in minutes, instead of waiting weeks or months for a scheduled shutdown. This is a strong competitive advantage for C5000 users.

- All TECO sensors are hot-swappable, saving the time and effort of a recalibration procedure when a sensor is replaced. All that is required is use the built-in normalization procedure and "zero" the replacement sensor. Your new sensor is ready to use.

- TECO consistency transmitters can be upgraded to act as a consistency controller, or function as multi-input controller, so that other process parameters can be adjusted for in the consistency control loop.

- TECO consistency transmitters can also be set up as a dilution controller.

- 100% Made in the USA.

- TECO consistency transmitters are very competitively priced.

More information at https://teco-inc.com

800-528-8997

Flow Meter Designed for Corrosive Slurries, Acids, Bases & Solvents

TECO Severe Applications Meter (SAM)

A patent pending magnetic flowmeter with abrasion resistant ceramic trim that exceeds the capabilities of Alumina or Yttria Zirconia. Capable of withstanding a variety of corrosive slurries, acids, bases, and solvents.800-528-8997

Severe Service Flow Meters by TECO

Stock Prep Solutions - Helping Paper Manufacturers Stay in Business

The concept behind stock prep is to manage the raw materials being added to the process so the finished stock meets the requirements of the paper machine and the final quality of the finished product. Finished stock is a suspension of fibers, additives, and impurities matching a defined level of quality, which ultimately determines the operation of the machinery and the quality of the final product. Most of the machines used for individual processes provide not only the desired effect, but also may produce undesirable side-effects. Implementing process controls to reduce or eliminate these undesirables help paper producers gain considerable improvements in quality, consistency, and yield.

This video introduces, and presents a case for, specific process instrumentation designed for stock prep.

http://www.teco-inc.com

800-528-8997

This video introduces, and presents a case for, specific process instrumentation designed for stock prep.

http://www.teco-inc.com

800-528-8997

What Are Rotameters?

|

| Rotameter (ABB) |

The rotameter has a number of advantages for use in a process. No external power or fuel is required, only the corresponding flow and gravity. They are simple devices that can be produced from low-cost materials, which is a main reason for the rotameter’s widespread use across many applications. Additionally, the area of the flow passage increases when the float moves, resulting in a linear relationship. The clear glass used also allows for a low risk of thermal shock and resulting issues from measuring chemicals. Rotameters also typically do not experience large drops in pressure, are simple to install, and are repeatable for long periods of time as long as they are operating under the same process conditions.

A few limitations exist in rotameters, the first of which relates to the fact the rotameter relies on displacement to function. A rotameter made to measure a certain substance at a particular temperature is only going to be accurate when measuring the substance and process qualities originally intended. While a rotameter can be scaled to measure different densities and viscosities, a limitation exists when the fluid characteristics being measured change in complexity. Secondly, while floats are often designed to function independent of viscosity, it can be difficult to ensure their effectiveness. Additionally, measurements being evaluated via rotameters can be uncertain when the float oscillates or near the bottom of the scale being used by the rotameter.

Certain fluids may also obscure the reading on the rotameter since the reading must be read through the flowing medium. This limitation can be countered by coupling he rotameter with a transducer in certain process applications. Another option for readability involves using a magnetic float that can be accompanied by a follower outside the tube, allowing the operator to easily read the measurement.

For more information about rotameters, visit https://teco-inc.com/ABB.

Positive Displacement Flowmeters

|

| Positive displacement flowmeter. (Badger Meter Blancett) |

The positive displacement flowmeter, in contrast with other types of flowmeters, directly measure the volume of fluid passing through the meter instead of employing inferential flow measurement. The rotational velocity of the rotor in the flow meter is directly proportional to the rate of flow. Electronic versions of positive displacement meters rely on magnets to activate sensors in their fluid chambers, whereas their non-electrical counterparts rely on the rotation being driven by the fluid flow.

The operating principle of the positive displacement meter may be simple, yet the flowmeter type offers a few specific advantages for industrial application. A main benefit of this flowmeter is a high level of accuracy due to its internal components. The accuracy of the flowmeter is directly related to the size of the clearances, or the space between the sealing faces.

These flowmeters are also particularly useful for handling a high range of viscosities. As the fluid viscosity increases with the positive displacement meter, less slippage or bypass will occur, meaning more total fluid will pass through the positive displacement meters. In addition to these design-based advantages, the positive displacement meter typically allows for excellent repeatability and linearity.

The longstanding use of positive displacement flowmeters across various industries has been a source of stability in terms of design, with the most recent advancements in positive displacement technology focusing on maintaining precision at lower costs.

There are a few known limitations for the use of positive displacement meters. The meters are not the optimal choice for measuring fluids with large particles, and are also non-ideal for measuring fluids with large air pockets. Additionally, systems using positive displacement meters need to account for slight pressure drops in the positive displacement meter. While the meters are able to accurately measure non-lubricating fluids, using positive displacement flowmeters to measure these types of liquids will not be as efficient as using the flowmeter for lubricating fluids. Overall, these types of flowmeters are a cost effective, accurate and volumetrically based flow measurement solution.

For more information on positive displacement flowmeters, call Thompson Equipment Company (TECO) at 800-528-8997 or visit https://teco-inc.com.

An Easy Way to Understand Laminar Flow vs. Turbulent Flow

|

| Image courtesy of Wikimedia.org |

In contrast to laminar flow, turbulent flow, caused by excessive kinetic energy in parts of a fluid flow, undergoes mixing and lateral irregularities characterized by eddies, recirculation, and apparent randomness. Fluid speed magnitude and direction changes chaotically in turbulent flow.

The video below provides a very simple, but very effective, demonstration of laminar and turbulent flow.

https://teco-inc.com

800-528-8997

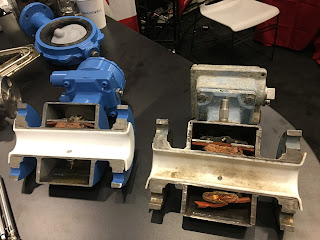

Get Your Process Flow Meters Remanufactured Instead of Buying New

|

| Cutaway before and after of remanufactured flow meter. |

Remanufactured flow meters meet or exceed all OEM specifications and performance standards. Here's how it works. Experienced technicians break down your flow meter to it's core components - flowtube, electronics, enclosure, flanges, and electrical. All parts are evaluated for wear and tear. All components are cleaned, primed, and painted. New electronics, flow sensors, liners, and electrical connections are installed. Once assembly is complete, the "remanufactured" flow meter goes through an exhaustive quality control process and is calibrated to NIST traceable standards using an advanced, state-of-the-art calibration facility.

|

| Remanufactured flow meter. |

Here is a summary of the benefits for choosing remanufacturing:

- All brands of flow meters are candidates.

- NIST traceable certificate is provided.

- Obsolete flow meters are no problem.

- No evaluation fees charged.

- Accessories are included.

- New warranty is given.

- Failure analysis is provided.

- Flow meters can be repurposed for severe service (enhanced during remanufacturing).

- Remanufacturing is GREEN and environmentally friendly.

For more information, visit this flow meter remanufacturing link or call 800-528-8997.

Industrial Plug Valves

|

| Plug valve diagram showing plug shape and orifice. |

Valves, of which there are many types, provide control over the flow rate, direction and routing of fluids in a processing operation. Flow can be started, stopped or modulated between zero and full rate using a properly sized and configured valve. Some valves enable media flow to be diverted to a selection of outlets, in lieu of a single inlet and outlet pair. Specialized valves regulate inlet or outlet pressure, or prevent fluid flow from going in an undesirable direction. All of these capabilities are packaged into differing valve product offerings that present a very large selection array to a process designer or engineer.

Industrial flow control valve types are generally classified according to the structure or arrangement contained within the valve body that provides obstruction to fluid flow. Some of the common types are ball, butterfly, gate, globe, and plug. Surely, there are more valve types, and this article is not intended to list them all. Some of our previous blogs have discussed selection considerations for gate, ball and butterfly valves. This article will focus on one of the oldest valve types, the plug valve.

Plug valves, like ball and butterfly valves, span from fully open to fully closed positions with a shaft rotation of 90 degrees. The “plug” in a plug valve is installed in the flow path within the valve body and rotated by means of a stem or shaft extending to the exterior of the body. Plugs are often tapered toward the bottom and are fitted to a seating surface in the valve body cavity that prevents fluid from bypassing the plug. An opening through the plug, the port, can be shaped to provide particular flow characteristics. There are numerous variants of the basic plug valve which may make it suitable for particular applications. One common variant is the lined or sleeved plug valve, with an insert or interior lining of material that creates an isolating barrier between the valve body and the media. This allows use of less expensive materials for the body construction that may be otherwise subject to corrosion by exposure to aggressive media.

Plug valve advantages:

- 90 degree rotation from open to closed provides fast operation.

- With proper configuration, can be well suited for frequent operation.

- Availability of corrosion resistant liner may provide comparative cost savings because valve body can be constructed of less expensive material.

- Design is simple and employs a low parts count.

- Valve can be serviced in place.

- Generally, low resistance to flow when fully open.

- Reliable leak-tight service due to tapered plug wedging action, replaceable sleeve, and injection of lubricant in some variants.

- Higher friction in the plug closure mechanism may require comparatively higher operating torque than other valve types.

- Without a specially designed plug, generally not well suited for throttling applications.

- Rapid shutoff delivered by plug design may not be suitable for some applications where hammering may occur.

Contact Thompson Equipment (TECO) for all your valve automation and valve repair needs.

https://teco-inc.com

800-528-8997

Subscribe to:

Posts (Atom)