You Get What You Pay For

Engineers and maintenance personnel who purchase

flow meters should remember that accurate instruments cost more based on their features and capabilities. It is always better to search for the type of flow meter best suited to a specific application before sacrificing features in favor of lower cost.

Flow meter specifiers should also take the time to examine long-term ownership costs. It may turn out that flow meters with low purchase prices may be very expensive to maintain. On the other hand, a flow meter with a high purchase price may require little or no service, and therefore lower cost of ownership over time. Lower purchase prices do not always represent the best long term, installed value.

Know Your Process

Users need to closely evaluate their overall process conditions, which include flow rates, pressure and temperature, and operating ranges. Be cautious of lower priced alternatives whose operating parameters don't fully support the requirements of the application.

All flow meters are affected to some extent by the process media and the way they are installed. As a result, their real-time performance will often be different from the controlled reference conditions under which they calibrated. There are some general rules that can be applied to flow meters to assist in reducing uncertainty:

- For the lowest uncertainty of measurement, positive displacement meters are generally the best option.

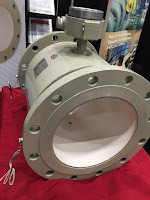

- Electromagnetic meters provide for the widest flow range and turbine meters are usually the best choice for the highest short-term repeatability.

- Despite their high initial cost, Coriolis meters are ideal for measuring particularly viscous substances and anywhere that the measurement of mass rather than volume is required.

General Selection Concepts:

- In general, flow meters with few or no moving parts require less time and attention than more complex flow meters.

- Meters constructed with multiple moving parts may malfunction because of dirt, grit or grime present in the process fluid.

- Flow meters with impulse lines can also plug or corrode.

- Flow meters with flow dividers and pipe bends sometimes suffer from abrasive media wear and blockages.

- Swings in ambient temperature may affect the internal dimensions of the flow meter and could require temperature compensation.

Calibration/Recalibration

The need for recalibration of flow meters is generally a function of how well the instrument is paired to its particular application. Should the application be critical, the flow meter accuracy should be checked at frequent, regular intervals. In some instances, mostly non-critical applications, recalibration may not be necessary for a period of years, becuase the application operating parameters never change.

Keep in mind though, that no matter what flow meter technology is chosen, overall system accuracy can never exceed the accuracy of the equipment used to perform the flow meter calibration. With that said, the most precise flow calibration systems on the market employ a positive displacement design. This type of calibrator, directly traceable to the National Institute of Standards and Technology (NIST) via water draw validation, provides total accuracy of at least 0.05 percent.

For more information on flow meter selection, installation,

calibration,

service, and

replacement contact

Thompson Equipment Company (TECO). Call them at 800-528-8997 or visit their web site at

https://teco-inc.com.