Variable area flow meters, also referred to as Rotameters, have diverse industrial processing applications that range from simple to sophisticated. The devices are easy to install, require no electrical connection, and provide direct flow rate reading. They provide fail-safe flow rate readings in a wide array of industrial applications.

Variable Area Flow Meters: An Overview

Developed by German inventor Karl Kueppers in 1908, Rotameters measure the volumetric flow rate of liquids and gases.

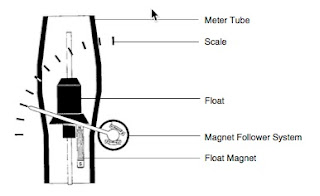

Important elements of a variable area flow meter include the tube and the float. Their operation is simple. The tube is fixed vertically and the fluid is fed from the bottom. It travels upward and exits from the top. The float remains at the bottom when no liquid is present and rises upward when fluid enters the tube.

The float inside the tube moves in proportion to the rate of fluid flow and the area between the tube wall and the float. When the float moves upward, the area increases while the differential pressure decreases. A stable position is reached when the upward force exerted by the fluid is equal to the weight of the float. A scale mounted on the tube records the flow rate of the liquid. Usually, the flow can be adjusted manually using a built-in valve.

Types of Variable Area Flow Meters

Variable area flow meters can be categorized by the type of tube they use, which relates to their ability to withstands various pressures, temperatures, process media, and cost. Process connection size and wetted part materials vary as a function the rotameter type and construction.

Plastic Tube Variable Area Flow Meter - For many non-corrosive, low-pressure air, water and gas flow applications. Made of machined acrylic or molded polycarbonate.

Plastic Tube Variable Area Flow Meter Applications:

- Water treatment systems

- Gas analyzers

- Air sampling equipment

- Desalinization equipment

- Medical equipment

- Photo processing equipment

- OEM machines

Glass Tube Variable Area Flow Meter - The basic glass variable area flow meter consists of borosilicate glass tube while the float is made of either glass, plastic, or stainless steel. The most common combination is a glass tube and metal float. This is suitable for a measure the flow rate of liquid of low to medium temperatures and pressures.

Glass Tube Variable Area Flow Meter Applications:

- Analytical instrumentation

- Industrial processes

- Chemical production

- Pharmaceutical production

- Oil & gas extraction

- Refining processes

- Fuel cell research

- Water treatment systems

Metal Tube Variable Area Flow Meter

Metal Tube Variable Area Flow Meter - Metal tube variable area flow meters are another type thatis suitable for temperatures and pressures beyond the physical and mechanical limits of glass tube versions. They are generally manufactured of stainless steel, aluminum, or brass. The piston position is determined by the mechanical and magnetic followers that can be read from the outside of the tube. They are suitable in situations where applications conditions would damage the glass metering tubes, such as steam applications.

Metal Tube Variable Area Flow Meter Applications:

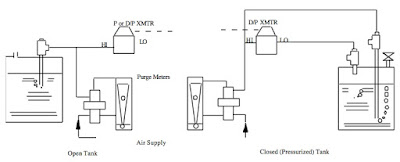

- Purge liquid or gas metering

- Liquid, gas, or oil flow measurement

- Chemical injection

- Rotating equipment flow measurement

- High-pressure flow meters for offshore oil platforms