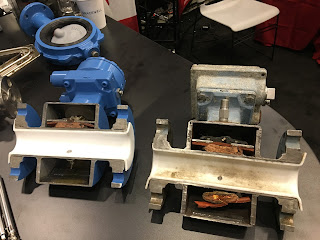

Many companies don't realize that when you have a failed mag meter or mass meter, it's often more cost-effective and efficient to have them restored to mint condition, than it is to replace them with new units.

But if you send meters to the original manufacturer they can disappear into their system for weeks or months. And you have no idea how long it will really take, or if it will fail again later from undetected problems. The fact is you can't afford the loss of productivity or downtime. But what if there were a place you could send broken flow meters that could save you money and time by restoring them to pristine condition. A cost-effective specialist who could guarantee rapid turn around time and premium customer service. A team of experienced professionals with the capabilities to keep equipment in service, even if it's no longer supported by others.

For a proven partner like this, there's only

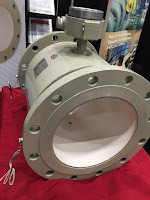

TECO. Established in 1947, TECO has become the global leader in restoration and customization of magnetic flow meters, Coriolis meters, and other process control instruments.

TECO understands that time is money, which is why they provide the fastest turnaround time in the

industry. They don't simply repair a broken part and return it, they do a full restoration and back the whole meter with a full warranty. Their quality control includes NIST traceable flow calibration, which is often required by regulatory agencies, and ISO 9000 standards. They also provide independent calibration to serve your preventive maintenance and metrology needs.

While their low cost, high quality work has made them the industry leader, it's their commitment to premium customer service that keeps their clients loyal. Extensive capabilities, combined with a focus on service, also means they can manufacture custom flow meter solutions to meet the demands of severe applications.

- Low cost, rapid restoration of mag meters, mass meters and other instruments.

- Pristine, like-new equipment, backed with a full warranty.

- Customized solutions and expert customer service you can trust.

It's all part of the package with TECO.

If you have failed mag meters, Coriolis meters, or other instruments, call TECO today. After receiving your equipment they'll turn around a quote in 48 hours or less - no return authorization required. To develop a customized solution for your needs, contact TECO.

Phone (504) 833-6381

Visit

https://teco-inc.com