For more information about severe service magnetic flowmeters, contact Thompson Equipment Company by calling 800-528-8997 or visit https://teco-inc.com.

Providing educational information on flowmeters, industrial control, process instrumentation, valves, and valve automation. Posts include interesting and unique industrial control applications, new product information, and ways of improving efficiency and saving money through proper maintenance, repair, service, and re-manufacturing.

Courtesy of Thompson Equipment Company | TECO-INC.COM | (504) 833-6381

Showing posts with label magmeter. Show all posts

Showing posts with label magmeter. Show all posts

New Batch of Severe Service Magmeters for Fracing Service from TECO

For more information about severe service magnetic flowmeters, contact Thompson Equipment Company by calling 800-528-8997 or visit https://teco-inc.com.

Magnetic Flow Meters: Basic Principles

Magnetic flow meters are used in many industrial applications. The device is preferred due to being cost-effective, providing accurate volumetric measurement, and an obstruction-less pathway for slurries and aggressive chemicals.

The operation of magnetic flow meters is different than other measurement devices. The post will highlight the basic principles of the device and also shed light on pros, cons, and industrial application.

The device creates a magnetic field to channel the flow of fluid through a pipe. As the fluid passes through the magnetic field, a voltage signal is created. The faster the fluid flows through the pipe, the higher the voltage produced by the device.

The voltage is picked up by electrode sensors that are located inside the tube. The signals are then conveyed to an electronic transmitter that processes the signal to determine the velocity of the fluid flow.

Magnetic flow meters can be installed in shorter meter runs since they don’t require much upstream and downstream runs. The volumetric flow meters have little or no moving parts and require less maintenance making them a cost-effective option for many industrial applications.

Magnetic flow meters can be installed in shorter meter runs since they don’t require much upstream and downstream runs. The volumetric flow meters have little or no moving parts and require less maintenance making them a cost-effective option for many industrial applications.

Another benefit of the industrial application of magnetic flow meters is that they have a low-pressure drop. Only a slight pressure drop results depending on the length of the tube. This results in more accurate measurement of the liquid flow velocity.

Magnetic flow devices are based on the principle of a linear relationship between the measuring signal and flow rate. In contrast, most other pressure devices work on the principle of a square law relationship. This results in a higher rangeability and accuracy of the magnetic meters.

An important thing that you should keep in mind is that the magnetic flow meters are susceptible to air bubbles. The device cannot differentiate between the process fluid and entrained air. So, the air bubbles will result in an incorrect reading. Air bubbles will cause the meter to give a high reading.

Another thing to remember is that the pipe should be filled completely with water. An incorrect reading will result if the pipe is not full. A solution for this is to install the sensor about 45 to 130 degree angle.

Since the flow meter is obstruction-less, the device is generally applied to measure the velocity of dirty, sanitary, abrasive, and corrosive liquids.

However, the device cannot be used for measuring velocities of liquids with low electrical conductivity such as boiler feed water, deionized water, and hydrocarbons. In addition, the device can also not measure the velocity of gasses.

Unlike insertion magnetic flow meters, inline flow meters don’t require a straight pipe. Moreover, they are best in assessing liquid with higher flow rates.

Magnetic flow meters are reliable in measuring velocities of conductive fluid. The devices have a wide range of industrial application, particularly in commodity transfer. They provide accurate reading and undergo less wear and tear. They are a reliable and cost-effective option for measuring the fluid flow of all conductive fluids.

The device can be used to accurately measure the fluid flow of untreated sewage water, processed water, and aggressive chemicals in water treatment, mining operations, and pulp and paper industries.

The operation of magnetic flow meters is different than other measurement devices. The post will highlight the basic principles of the device and also shed light on pros, cons, and industrial application.

Basic Principle of Magnetic Flow Meters

Magnetic flow meters are also known as electromagnetic flow meters or mag meters. The principle of magnetic flow meter is based on Faraday’s Law of Electromagnetic induction. The law states that a voltage produced across a conductor as it moves through the magnetic field at right angles is directly proportional to the velocity of that conductor.The device creates a magnetic field to channel the flow of fluid through a pipe. As the fluid passes through the magnetic field, a voltage signal is created. The faster the fluid flows through the pipe, the higher the voltage produced by the device.

The voltage is picked up by electrode sensors that are located inside the tube. The signals are then conveyed to an electronic transmitter that processes the signal to determine the velocity of the fluid flow.

Benefits of Magnetic Flow Meters

Magnetic flow meters can be installed in shorter meter runs since they don’t require much upstream and downstream runs. The volumetric flow meters have little or no moving parts and require less maintenance making them a cost-effective option for many industrial applications.

Magnetic flow meters can be installed in shorter meter runs since they don’t require much upstream and downstream runs. The volumetric flow meters have little or no moving parts and require less maintenance making them a cost-effective option for many industrial applications.Another benefit of the industrial application of magnetic flow meters is that they have a low-pressure drop. Only a slight pressure drop results depending on the length of the tube. This results in more accurate measurement of the liquid flow velocity.

Magnetic flow devices are based on the principle of a linear relationship between the measuring signal and flow rate. In contrast, most other pressure devices work on the principle of a square law relationship. This results in a higher rangeability and accuracy of the magnetic meters.

An important thing that you should keep in mind is that the magnetic flow meters are susceptible to air bubbles. The device cannot differentiate between the process fluid and entrained air. So, the air bubbles will result in an incorrect reading. Air bubbles will cause the meter to give a high reading.

Another thing to remember is that the pipe should be filled completely with water. An incorrect reading will result if the pipe is not full. A solution for this is to install the sensor about 45 to 130 degree angle.

Application of Magnetic Flow Meters

Magnetic flow meters can measure velocities of all conductive liquids including water, slurries, and acids. More specifically, the device can measure velocities of liquids with electrical conductivity greater than 5μS/cm.Since the flow meter is obstruction-less, the device is generally applied to measure the velocity of dirty, sanitary, abrasive, and corrosive liquids.

However, the device cannot be used for measuring velocities of liquids with low electrical conductivity such as boiler feed water, deionized water, and hydrocarbons. In addition, the device can also not measure the velocity of gasses.

Types of Magnetic Flow Meter

You can find three common types of a magnetic flow meter in the market. The devices are suitable for different industrial application.Insertion Magnetic Flow Meter

The insertion magnetic flow meter is best for measuring liquid flow in large pipes. The device is simple to install and deliver accurate measurement across a range of pipe sizes.Inline Magnetic Flow Meter

Inline magnetic flow meter is ideal for situations where high accuracy is necessary. The device is generally used for measuring the liquid flow of slurries, wastewater, food, and pulp.Unlike insertion magnetic flow meters, inline flow meters don’t require a straight pipe. Moreover, they are best in assessing liquid with higher flow rates.

Low-flow Magnetic Meters

Low-flow magnetic meters are great for assessing liquid with low flow rates. They are designed in a way to prevent fouling. Similar to insertion magnetic flow meters, the low-flow meters do not require straight pipe. In addition, the device can be used in situations where little space is available between the elbow and the meter.Magnetic flow meters are reliable in measuring velocities of conductive fluid. The devices have a wide range of industrial application, particularly in commodity transfer. They provide accurate reading and undergo less wear and tear. They are a reliable and cost-effective option for measuring the fluid flow of all conductive fluids.

The device can be used to accurately measure the fluid flow of untreated sewage water, processed water, and aggressive chemicals in water treatment, mining operations, and pulp and paper industries.

For more information on magnetic flow meters, contact Thompson Equipment Company (TECO) by calling 800-528-8997 or by visiting https://teco-inc.com.

Electromagnetic Flow Metering

|

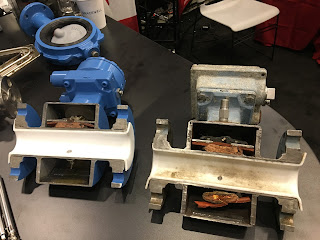

| Cutaways of electromagnetic flow meters - one removed from service (right) and one remanufactured (left). |

Electromagnetic flow metering is based on the principles of Michael Faraday's 1832 discovery. When a conductive liquid, such as water, is moved through a magnetic field a voltage is induced in the liquid at right angles to the magnetic field. The size of the voltage is directly proportional to the volume flow rate. This induced voltage is detected by sensors known as electrodes. These electrodes transfer the voltage signal to the processing electronics where it can be converted into a usable industrial standard signal.

It's important that the flow meter tube is non-magnetic, and austenitic stainless steel is the most commonly used material. It's also essential that the flow meter tube has a lining that electrically insulates it from the liquid inside, and provides a non-reactive barrier with any corrosive liquids being measured. Distinguishing between flow induced voltage changes, electrochemical noise, and plant induced noise, is a barrier to accurate electromagnetic flow metering. This can be particularly difficult in dirty and industrial applications. The choice of electromagnetic flowmeters with advanced noise suppression can mitigate unwanted noise and provide extremely high orders of accuracy as a result.

To ensure that your electromagnetic flow meters will be optimized for safety, longevity, and performance, the advice of a qualified flow instrumentation expert should be sought out. That expert will be able to help you with the best selection of the appropriate flow device for your specific application, be it electromagnetic flow meters or another flow technology.

Magnetic Flow Meters for Abrasive Service

Magnetic flow meters (magmeters) apply Faraday’s Law of Electromagnetic Induction to measure flow. They are specifically designed for conductive fluids like water, acids, caustic liquids, and slurries.

Magnetic flowmeters differ in materials, size, corrosion resistance, pressure and temperature performance. Properly applying magnetic flow meters for abrasive and/or erosive slurry measurement is one of the most challenging applications for plant engineers and maintenance managers to address. The proper combination of design components is critical.

If you have a challenging flow measurement application that involves abrasive or erosive media, contact TECO for assistance. A short conversation with one of our application engineers will save you a great deal of time and money.

Thompson Equipment Company

http://www.teco-inc.com

800-528-8997

Magnetic Flowmeters for Measuring the Frac Fluid

A piece of equipment used in hydraulic fracturing is the blender truck. It contains the equipment used to prepare and measure the "frac fluid". Frac fluid is composed of water, sand, specialty chemicals, and gels, and is highly erosive and sometimes corrosive. This "blended" mixture of sand, water and chemicals is then injected into a well to hydraulically open cracks in the rock layers below. By opening the cracks, trapped natural gas and petroleum is released and flows more freely.

Magnetic flowmeters are employed to measure the frac fluid flow and volume. These flowmeters must accurately meter the frac fluid into the well, stand up to the continual erosive media, and be durable enough to handle the harsh ambient conditions. Standard process magmeters experience shortened lifespans under these conditions and must be pulled from service and repaired. A better alternative is a severe service flowmeters designed specifically for this service.

Thompson Equipment Company (TECO) manufactures an electromagnetic flowmeter (magmeter) designed for frac fluid flow metering. The TECO design incorporates two significant features to improve performance and extend operating life:

Thompson Equipment Company (TECO) manufactures an electromagnetic flowmeter (magmeter) designed for frac fluid flow metering. The TECO design incorporates two significant features to improve performance and extend operating life:

- A ceramic sleeved liner made of “magnesia partially stabilized zirconia”

- The use of solid tungsten electrodes.

Electromagnetic Flow Meters for Accurate Measurement of Flowing Conductive Fluids and Slurries

|

| Magnetic Flow Meter (Badger Meter) |

Electromagnetic flow meters employ Faraday’s law of electromagnetic induction, whereby voltage is induced when a conductor moves through a magnetic field. The liquid acts as the conductor, with energized coils outside the flow tube creating the magnetic field. The produced voltage is directly proportional to the flow rate. Magnetic flow meter technology is not affected by temperature, pressure, or density of the subject fluid.

Electromagnetic flow meters tend to be heavy in larger sizes and may be prohibitively expensive for some purposes. However, irrespective of price and size, there are multiple reasons why magnetic flow meters are the instrument of choice for certain applications. They are resistant to corrosion and their ability to accurately measure dirty fluids makes them very suitable for wastewater measurement. As mentioned, there are no moving parts in a magnetic flow meter, keeping maintenance to a minimum. Power requirements are also low. Electromagnetic flow meters are available in a wide range of configurations, sizes, and construction materials to accommodate various process installation

requirements.

|

| Severe service flow meter. (TECO) |

Contact Thompson Equipment Company (TECO) with any magnetic flow meter requirement. Their decades of applying, repairing, re-manufacturing, and designing magnetic flow meters will assure a successful implementation.

Severe Service Magmeters for Fracing Operations

Proven in the heat of a West Texas summer, and the cold of an Alberta winter, this TECO magmeter is designed from the ground up to withstand corrosive slurries, acids, bases and solvents.

|

| Severe Application Meter (TECO) |

Calling upon sixty-plus years experience in magmeter application, failure analysis, repair, and design, TECO developed several innovative magmeter features intended to improve longevity in fracing operations.

|

| FRAC Trucks |

Second, TECO developed electrodes built from a solid tungsten carbide billet, which afford unparalleled wear resistance. Given the sand density in the frac fluid, noise reduction is critically important; so, the tungsten carbide is polished leaving a hard, smooth finish that significantly reduces noise in the electrode circuit.

|

| Erosive sand tears up other magmeters. |

|

| Internal view of SAM after 500,000,000 pounds of sand flowed though the core. Upon inspection, the customer found the flow tube to be looking “brand new”. |

Download the PDF version of this article here.

Contact TECO by visiting https://teco-inc.com of call 800-528-8997 for more information.

Failed Flowmeter - Replace with New or Remanufactured?

Many companies don't realize that when you have a failed mag meter or mass meter, it's often more cost-effective and efficient to have them restored to mint condition, than it is to replace them with new units.

But if you send meters to the original manufacturer they can disappear into their system for weeks or months. And you have no idea how long it will really take, or if it will fail again later from undetected problems. The fact is you can't afford the loss of productivity or downtime. But what if there were a place you could send broken flow meters that could save you money and time by restoring them to pristine condition. A cost-effective specialist who could guarantee rapid turn around time and premium customer service. A team of experienced professionals with the capabilities to keep equipment in service, even if it's no longer supported by others.

For a proven partner like this, there's only TECO. Established in 1947, TECO has become the global leader in restoration and customization of magnetic flow meters, Coriolis meters, and other process control instruments.

TECO understands that time is money, which is why they provide the fastest turnaround time in the

industry. They don't simply repair a broken part and return it, they do a full restoration and back the whole meter with a full warranty. Their quality control includes NIST traceable flow calibration, which is often required by regulatory agencies, and ISO 9000 standards. They also provide independent calibration to serve your preventive maintenance and metrology needs.

While their low cost, high quality work has made them the industry leader, it's their commitment to premium customer service that keeps their clients loyal. Extensive capabilities, combined with a focus on service, also means they can manufacture custom flow meter solutions to meet the demands of severe applications.

If you have failed mag meters, Coriolis meters, or other instruments, call TECO today. After receiving your equipment they'll turn around a quote in 48 hours or less - no return authorization required. To develop a customized solution for your needs, contact TECO.

Phone (504) 833-6381

Visit https://teco-inc.com

But if you send meters to the original manufacturer they can disappear into their system for weeks or months. And you have no idea how long it will really take, or if it will fail again later from undetected problems. The fact is you can't afford the loss of productivity or downtime. But what if there were a place you could send broken flow meters that could save you money and time by restoring them to pristine condition. A cost-effective specialist who could guarantee rapid turn around time and premium customer service. A team of experienced professionals with the capabilities to keep equipment in service, even if it's no longer supported by others.

For a proven partner like this, there's only TECO. Established in 1947, TECO has become the global leader in restoration and customization of magnetic flow meters, Coriolis meters, and other process control instruments.

TECO understands that time is money, which is why they provide the fastest turnaround time in the

industry. They don't simply repair a broken part and return it, they do a full restoration and back the whole meter with a full warranty. Their quality control includes NIST traceable flow calibration, which is often required by regulatory agencies, and ISO 9000 standards. They also provide independent calibration to serve your preventive maintenance and metrology needs.

While their low cost, high quality work has made them the industry leader, it's their commitment to premium customer service that keeps their clients loyal. Extensive capabilities, combined with a focus on service, also means they can manufacture custom flow meter solutions to meet the demands of severe applications.

- Low cost, rapid restoration of mag meters, mass meters and other instruments.

- Pristine, like-new equipment, backed with a full warranty.

- Customized solutions and expert customer service you can trust.

If you have failed mag meters, Coriolis meters, or other instruments, call TECO today. After receiving your equipment they'll turn around a quote in 48 hours or less - no return authorization required. To develop a customized solution for your needs, contact TECO.

Phone (504) 833-6381

Visit https://teco-inc.com

Flow Meter Designed for Corrosive Slurries, Acids, Bases & Solvents

TECO Severe Applications Meter (SAM)

A patent pending magnetic flowmeter with abrasion resistant ceramic trim that exceeds the capabilities of Alumina or Yttria Zirconia. Capable of withstanding a variety of corrosive slurries, acids, bases, and solvents.800-528-8997

Severe Service Flow Meters by TECO

World's First Magnetic Flowmeter Developed Specifically for Hydraulic Fracing

When suspended solids are mixed with a liquid (such as water), a mud-like substance referred to as a “slurry” is formed. Slurries are challenging because of their abrasive nature. Add a highly caustic or acidic condition to the slurry, and the magnetic flowmeters (Magmeters) used to measure flow become particularly susceptible to failure. In these situations off-the-shelf magnetic flowmeters won’t last, so consideration must be given to custom flowmeters built specifically to withstand the application’s unique requirements. Hydraulic fracturing (fracing) is one industry where the movement and handling of slurries is very common, and specially designed Magmeters should be used.

Thompson Equipment (TECO) is now offering their "Severe Application Meter (SAM)" (patent pending) which is specifically designed as the world's first Magmeter developed specifically for the hydraulic fracing industry. It is designed with an impact and wear resistant ceramic liner, solid tungsten carbide billet electrodes, and quick change Victaulic flanges. The SAM can also be retrofitted to the customers existing electronic secondary system, such as Rosemount, E+H, Yokagawa, etc.For more information, contact TECO by calling (504) 833-6381 or by visiting https://www.teco-inc.com.

The Magmeter Zone - Don't Let Your Flow Meters Die Here

Subscribe to:

Comments (Atom)