|

| The graph above displays the actual results from lab verification samples taken from the defiberlizer. |

Problem / Issue:

Pulp Mill Consistency Measurement Requires Accurate Measurement over a Wide Range of Consistency Levels.

Overview:

The overall throughput (TPD) of the fiber line is traditionally calculated from a single consistency measurement device. This measurement must be accurate and repeatable.

TECO Solution:

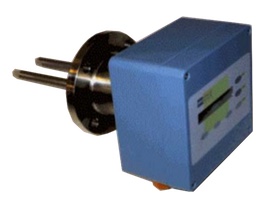

C9700 Fixed Wing Consistency Sensor.

How the TECO Solution Solves The Problem...

The TECO C9700 Fixed Wing Consistency Sensor is designed to accurately measure over a wide consistency range, including low consistency swings from variations in blow tank levels. This sensor has proven consistency ranges from 1.5 % to 7.0%, over a wide range of velocity (flow) rates.

As an example, the above graph displays the results from a southern kraft pulp mill application, after the blow tank, prior to the defiberlizer.

The overall throughput (TPD) of the fiber line is traditionally calculated from a single consistency measurement device. This measurement must be accurate and repeatable.

TECO Solution:

C9700 Fixed Wing Consistency Sensor.

How the TECO Solution Solves The Problem...

The TECO C9700 Fixed Wing Consistency Sensor is designed to accurately measure over a wide consistency range, including low consistency swings from variations in blow tank levels. This sensor has proven consistency ranges from 1.5 % to 7.0%, over a wide range of velocity (flow) rates.

As an example, the above graph displays the results from a southern kraft pulp mill application, after the blow tank, prior to the defiberlizer.

Benefits

- Wide Consistency Range – accurate across a variety of consistency levels

- Simple / Reliable Probe Design – no moving parts or maintenance issues

- Stable Calibration and Excellent Repeatability – for complete consistency control

Who is it Important to?

- Pulp Mill Superintendent

- Bleach Plant Superintendent

- Process Control Engineer

- Maintenance Manager

- Instrument Superintendent