http://www.teco-inc.com

800-528-8997

Providing educational information on flowmeters, industrial control, process instrumentation, valves, and valve automation. Posts include interesting and unique industrial control applications, new product information, and ways of improving efficiency and saving money through proper maintenance, repair, service, and re-manufacturing.

Courtesy of Thompson Equipment Company | TECO-INC.COM | (504) 833-6381

|

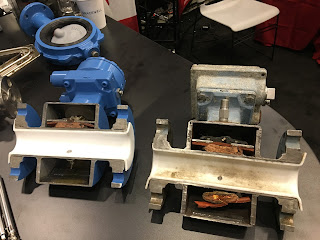

| Cutaways of electromagnetic flow meters - one removed from service (right) and one remanufactured (left). |

Flow measurement is a critical aspect of plant operation in the Chemical Processing Industry (CPI). Users choosing equipment to meter the flow of liquid or gas processes must consider a wide range of factors to arrive at an optimal solution Experience has shown there are significant differences between meter technologies, with each type of device having its own advantages and disadvantages for processing facilities

Flow measurement is a critical aspect of plant operation in the Chemical Processing Industry (CPI). Users choosing equipment to meter the flow of liquid or gas processes must consider a wide range of factors to arrive at an optimal solution Experience has shown there are significant differences between meter technologies, with each type of device having its own advantages and disadvantages for processing facilities |

| Fracing illustration (USGS) |

Frac sand is very erosive and the high pressure and corrosive chemicals complicate things exponentially. Any flowmeter used in fracing applications must not only be rugged enough to withstand these harsh conditions, but the flowmeter must also provide the accuracy required for reliable data reporting to supervisory agencies. Cost-effectively meeting accuracy and longevity requirements for these applications can be frustrating.

Frac sand is very erosive and the high pressure and corrosive chemicals complicate things exponentially. Any flowmeter used in fracing applications must not only be rugged enough to withstand these harsh conditions, but the flowmeter must also provide the accuracy required for reliable data reporting to supervisory agencies. Cost-effectively meeting accuracy and longevity requirements for these applications can be frustrating. By specifying magnetic flowmeters, specialized for fracing, not only do operators save money through increased uptime and decreased health, safety and environmental risk, but also through reduced costs related to flowmeter purchase and repair.

By specifying magnetic flowmeters, specialized for fracing, not only do operators save money through increased uptime and decreased health, safety and environmental risk, but also through reduced costs related to flowmeter purchase and repair.