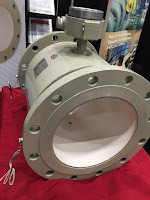

Hydraulic fracturing is the drilling process where layers of bedrock are cracked and spilt using hydraulic fluids to free up and extract oil and natural gas trapped within. TECO is a manufacturer of

severe service magnetic flowmeters designed specifically for the hydraulic fracturing industry.

We at TECO believe its important to fully understand an industry's unique processes, challenges, and terminology. By doing so we gain a deep industry knowledge. This knowledge facilitates better communication. Better communication increases understanding and reduces mistakes and errors.

There are very few situations where this isn't the best track to follow. But we found one.

We always tried to do our best by being clear, accurate, and following industry standards. But sometimes you just have to know when to give up. Such is the case with the never-ending "fracing vs. fracking" debate.

This isn't the first essay on the subject, and it won't be the last. It's just that, we here at TECO, have decided to change our online communications approach, based upon some pretty strong data.

While the Oil and Gas industry prefer leaving that lower case "k" out, it's become quite clear that Mr. Google and Mr. Webster decided the "k" needs to be there. And when you're a company making

great flow meters, and trying to let people know how good they are, it's makes a world of difference in getting found on the search engines.

It's no secret that Oil and Gas industry people clearly prefer the use of frac or fracing. There are quite a few instances where industry leaders have strongly argued that frac or fracing are the only acceptable spellings. TECO too, decided the industry preferred version was the way to go, and decided that all of our efforts in online marketing and communications would follow suit. We were sure that by sticking to the use of the industry preferred spelling, we'd be in a perfect position to be seen by all the industry professionals searching for "

fracing flow meters".

But that didn't happen. Mr. Google wasn't buying it. Search engine results were disappointing. We needed to find out what we were doing wrong.

After careful review of our online content, and use of keywords, we determined it was that lousy lowercase "k". Turns out it makes an insane amount of difference when people use a search engine.

For example, in one test, using a generic keyword tracking tool, we found that the term "fracing" returns a total of 1187 searches, while the term "fracking" returns an astounding 87,836 searches! That means "fracking" is searched for 74 times more than "fracing". You can't ignore that.

Additionally, when you review the Google Trends graph below, you see a vivid illustration of the usage (and trends) for the terms Frac, Frack, Fracing and Fracking (it's pretty clear that Fracking is the winner).

|

| Click for larger view. |

But this graph also reveals another important geographic clue. You'll note that the term Frac is used in the specific states where the actual drilling is happening, which makes sense because that's where the fracing industry professionals are. And we want to make sure we reach them. So, our conclusion and online marketing plan may not surprise you.

We'll use both. 😀