Providing educational information on flowmeters, industrial control, process instrumentation, valves, and valve automation. Posts include interesting and unique industrial control applications, new product information, and ways of improving efficiency and saving money through proper maintenance, repair, service, and re-manufacturing.

Courtesy of Thompson Equipment Company | TECO-INC.COM | (504) 833-6381

Honoring the People Who Protect Our Freedom

Through the observance of Veterans Day we celebrate and honor America's veterans for their patriotism, love of country, willingness to serve, and sacrifice for the common good. We recognize and celebrate those who have chosen to serve in the United States military and take an oath to defend the United States and our Constitution, from all enemies, foreign and domestic.

Veterans Day was originally called Armistice Day because of the November 11 Armistice that ended World War I. In 1954 it was officially changed to Veterans Day to include Veterans of all wars. Thompson Equipment Company thanks our Veterans, past and present, for serving our country and protecting our freedom.

What Are Valve Actuators?

Valve actuators are categorized based upon a number of factors including power source available, torque necessary to operate the valve, installation location, and the need for automatic actuation. Actuators are devices which supply the force and motion to open and close valves. They can be manually, pneumatically, hydraulically, or electrically operated. In common industrial usage, the term actuator generally refers to a device which employs a non-human power source and can respond to a controlling signal.

Electric Actuators

Electric motors permit manual, semi-automatic, and automatic operation of the valve. Motors are used mostly for open-close functions, although they are adaptable to positioning the valve to any point opening as illustrated in Figure 33. The motor is usually a, reversible, high speed type connected through a gear train to reduce the motor speed and thereby increase the torque at the stem. Direction of motor rotation determines direction of disk motion. The electrical actuation can be semi-automatic, as when the motor is started by a control system. A handwheel, which can be engaged to the gear train, provides for manual operating of the valve. Limit switches are normally provided to stop the motor automatically at full open and full closed valve positions. Limit switches are operated either physically by position of the valve or torsionally by torque of the motor.

Pneumatic actuators as illustrated in Figure 34 provide for automatic or semi- automatic valve operation. These actuators translate an air signal into valve stem motion by air pressure acting on a diaphragm or piston connected to the stem. Pneumatic actuators are used in throttle valves for open-close positioning where fast action is required. When air pressure closes the valve and spring action opens the valve, the actuator is termed direct- acting. When air pressure opens the valve and spring action closes the valve, the actuator is termed reverse- acting. Duplex actuators have air supplied to both sides of the diaphragm. The differential pressure across the diaphragm positions the valve stem. Automatic operation is provided when the air signals are automatically controlled by circuitry. Semi-automatic operation is provided by manual switches in the circuitry to the air control valves.

Hydraulic actuators provide for semi-automatic or automatic positioning of the valve, similar to the pneumatic actuators. These actuators use a piston to convert a signal pressure into valve stem motion. Hydraulic fluid is fed to either side of the piston while the other side is drained or bled. Water or oil is used as the hydraulic fluid. Solenoid valves are typically used for automatic control of the hydraulic fluid to direct either opening or closing of the valve. Manual valves can also be used for controlling the hydraulic fluid; thus providing semi-automatic operation.

For more information on valve actuators and valve automation, contact Thompson Equipment Company (TECO) by calling 800-528-8997 of visit the valve automation area of their web site here.

Types of actuators include:

- Manual handwheel or lever

- Electrical motor

- Pneumatic

- Hydraulic

|

| Gear Operator |

Manual Actuators

Manual actuators are capable of placing the valve in any position but do not permit automatic operation. The most common type mechanical actuator is the handwheel. This type includes handwheels fixed to the stem, hammer handwheels, and handwheels connected to the stem through gears.Gear Operators

If additional mechanical advantage is necessary for a manually-operated valve, the valve bonnet is fitted with manually-operated gear heads as illustrated in Figure 32. A special wrench or handwheel attached to the pinion shaft permits one individual to operate the valve when two individuals might be needed without the gear advantage. Because several turns of the pinion are necessary to produce one turn of the valve stem, the operating time of large valves is exceptionally long. The use of portable air motors connected to the pinion shaft decreases the valve operating time.

Electric Actuators

|

| Electric Actuator |

Pneumatic Actuators

|

| Pneumatic Actuator |

Hydraulic Actuators

|

| Hydraulic Actuator |

For more information on valve actuators and valve automation, contact Thompson Equipment Company (TECO) by calling 800-528-8997 of visit the valve automation area of their web site here.

The Top 10 Fluid Flow Measurement Application Questions

|

| Variable area flow meter (ABB) |

|

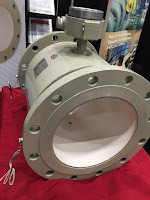

| Severe service flow meter (TECO) |

- Is the measured process media a liquid or a gas?

- Is the flow measurement occurring in a pipe or in an open channel?

- What is the the flow rate?

- How much does the flow vary?

- If liquid, is it clean or does it contain suspended solids or air bubbles?

- What accuracy is required?

- How much head loss by the flowmeter is permissible?

- Is the flow corrosive or erosive?

- What types of flowmeter technologies can be accommodated in the location?

- What types of post installation service is available in area?

|

| Positive Displacement Meter (Blancett) |

Selecting and configuring a flow measurement device properly, and assuring that installation is done correctly, are necessary tasks to achieving optimal flow meter performance. Reach out to a flow meter specialist with your flow application. By combining your process knowledge with their product application expertise, an effective and long lasting solution will result.

For more information about any flow measurement application, contact Thompson Equipment. The can be reached by calling 800-528-8997 or by visiting https://teco-inc.com.

Flow Measurement for Hydraulic Fracturing and the Production of Shale Gas

|

| Figure 1. Illustration of the fracing (fracking) process. (Image courtesy of EPA.gov) |

A “conventional” gas reservoir is produced from sands and carbonates (such as limestone). In the conventional reservoir, the gas is in interconnected pore spaces, much like a kitchen sponge, that allow easier flow to a well. In an "unconventional" gas reservoir, such as shale, the reservoir must be mechanically “stimulated” to create additional permeability and free the gas for collection. Permeability refers to the capacity of a porous, sediment, soil – or rock in this case – to transmit a fluid. Unconventional reservoirs include tight gas (low-porosity sandstones and carbonate reservoirs) and coal bed methane (CBM – gas produced from coal seams).

For shale gas, hydraulic fracturing (known as "fracing" or "fracking") of a reservoir is the preferred stimulation method (figure 1). This typically involves injecting pressurized fluids to stimulate or fracture shale formations and release the natural gas. Sand pumped in with the fluids (often water) helps to keep the fractures open. The type, composition and volume of fluids used depend largely on the geologic structure, formation pressure and the specific geologic formation and target for a well. If water is used as the pressurized fluid, as much as 20 percent can return to the surface via the well (known as flow back). This water can be treated and reused – in fact, reuse of flow back fluids for subsequent hydraulic fracture treatments can significantly reduce the volume of wastewater generated by hydraulic fracturing.

The hydraulic fracturing process was used in conventional limestone and sandstone reservoirs for decades before the onset of the shale revolution. But it was not until the 1970s that significant attempts to apply the technology to gas shale were made, pioneered by DOE research and demonstration project cost-sharing with industry in such ventures as the Eastern Gas Shales Project (1976-92).

Another major technology often employed in producing natural gas from shale is horizontal drilling. The shallow section of shale wells are drilled vertically (much like a traditional conventional gas well). Just above the target depth – the place where the shale gas formation exists – the well deviates and becomes horizontal. At this location, horizontal wells can be oriented in a direction that maximizes the number of natural fractures intersected in the shale. These fractures can provide additional pathways for the gas that is locked away in the shale, once the hydraulic fracturing operation takes place.

Accurate flow measurement is important in fracking applications and required for reliable data reporting to supervisory agencies. The preferred technology for measuring flow in fracking applications are magnetic flowmeters (magmeters), primarily for their non-obstructive flow path, accuracy and reasonable cost. There are caveats associated with applying magmeters in fracking applications and selection of specialized flow meter components is required. Fracking sand is very erosive and chemicals mixed with the fracking water can be erosive. Any flow meter used in fracking applications must be rugged enough to withstand these harsh conditions.

|

| Flow meter designed for fracking applications (as well as for other abrasive slurries) by TECO. |

An excellent solution that provides all the the virtues of magnetic flowmeters and overcomes performance and longevity issues referred to as "severe service flowmeters" or "slurry flow meters" designed with components matched specifically to withstand the mechanical and chemical abuse they will see. Their modifications include:

- A ceramic sleeved liner made of magnesia partially stabilized zirconia. This ceramic can handle the abrasion and chemical attack with very little degradation.

- Highly polished, ultra-smooth Tungsten electrodes. The Tungsten provides outstanding wear resistance while the high-polish reduces electrical noise introduced in the electrode circuitry.

- Special coatings, or paints, to provide exterior protection.

For more information on fracking (or fracing) magnetic flow meters, contact Thompson Equipment Company (TECO) by calling 800-528-8997 or visit https://teco-inc.com.

Source: How is Shale Gas Produced? https://www.energy.gov/fe/shale-gas-101

Handbook for Variable Area Flowmeters

This “Handbook for Variable Area Flowmeters“, courtesy of ABB and Thompson Equipment, is a practical guide for the user with selection criteria for real applications (see Check List/Parameter Questionnaire), correction factors, Accuracy Classes, corrosion resistance tables and much more. A separate flyer with actual pictures demonstrate the application versatility.

Answers are provided to frequently asked questions about this measurement principle (see Page 20) and we have incorporated a preferential quick ship program for the most popular instrument versions.

We hope that this Handbook provides you with a practical selection guide; naturally our sales team is always ready to provide you with any personal assistance you may require.

Thompson Equipment (TECO)

800-528-8997

https://teco-inc.com

Answers are provided to frequently asked questions about this measurement principle (see Page 20) and we have incorporated a preferential quick ship program for the most popular instrument versions.

We hope that this Handbook provides you with a practical selection guide; naturally our sales team is always ready to provide you with any personal assistance you may require.

Thompson Equipment (TECO)

800-528-8997

https://teco-inc.com

What Are Variable Area Flow Meters?

Variable area flow meters, also referred to as Rotameters, have diverse industrial processing applications that range from simple to sophisticated. The devices are easy to install, require no electrical connection, and provide direct flow rate reading. They provide fail-safe flow rate readings in a wide array of industrial applications.

Developed by German inventor Karl Kueppers in 1908, Rotameters measure the volumetric flow rate of liquids and gases.

Important elements of a variable area flow meter include the tube and the float. Their operation is simple. The tube is fixed vertically and the fluid is fed from the bottom. It travels upward and exits from the top. The float remains at the bottom when no liquid is present and rises upward when fluid enters the tube.

The float inside the tube moves in proportion to the rate of fluid flow and the area between the tube wall and the float. When the float moves upward, the area increases while the differential pressure decreases. A stable position is reached when the upward force exerted by the fluid is equal to the weight of the float. A scale mounted on the tube records the flow rate of the liquid. Usually, the flow can be adjusted manually using a built-in valve.

Variable area flow meters can be categorized by the type of tube they use, which relates to their ability to withstands various pressures, temperatures, process media, and cost. Process connection size and wetted part materials vary as a function the rotameter type and construction.

Plastic Tube Variable Area Flow Meter - For many non-corrosive, low-pressure air, water and gas flow applications. Made of machined acrylic or molded polycarbonate.

Plastic Tube Variable Area Flow Meter Applications:

Glass Tube Variable Area Flow Meter - The basic glass variable area flow meter consists of borosilicate glass tube while the float is made of either glass, plastic, or stainless steel. The most common combination is a glass tube and metal float. This is suitable for a measure the flow rate of liquid of low to medium temperatures and pressures.

Glass Tube Variable Area Flow Meter Applications:

Metal Tube Variable Area Flow Meter - Metal tube variable area flow meters are another type thatis suitable for temperatures and pressures beyond the physical and mechanical limits of glass tube versions. They are generally manufactured of stainless steel, aluminum, or brass. The piston position is determined by the mechanical and magnetic followers that can be read from the outside of the tube. They are suitable in situations where applications conditions would damage the glass metering tubes, such as steam applications.

Metal Tube Variable Area Flow Meter Applications:

Variable Area Flow Meters: An Overview

Developed by German inventor Karl Kueppers in 1908, Rotameters measure the volumetric flow rate of liquids and gases.

Important elements of a variable area flow meter include the tube and the float. Their operation is simple. The tube is fixed vertically and the fluid is fed from the bottom. It travels upward and exits from the top. The float remains at the bottom when no liquid is present and rises upward when fluid enters the tube.

The float inside the tube moves in proportion to the rate of fluid flow and the area between the tube wall and the float. When the float moves upward, the area increases while the differential pressure decreases. A stable position is reached when the upward force exerted by the fluid is equal to the weight of the float. A scale mounted on the tube records the flow rate of the liquid. Usually, the flow can be adjusted manually using a built-in valve.

Types of Variable Area Flow Meters

Variable area flow meters can be categorized by the type of tube they use, which relates to their ability to withstands various pressures, temperatures, process media, and cost. Process connection size and wetted part materials vary as a function the rotameter type and construction.

Plastic Tube Variable Area Flow Meter - For many non-corrosive, low-pressure air, water and gas flow applications. Made of machined acrylic or molded polycarbonate.

Plastic Tube Variable Area Flow Meter Applications:

- Water treatment systems

- Gas analyzers

- Air sampling equipment

- Desalinization equipment

- Medical equipment

- Photo processing equipment

- OEM machines

Glass Tube Variable Area Flow Meter - The basic glass variable area flow meter consists of borosilicate glass tube while the float is made of either glass, plastic, or stainless steel. The most common combination is a glass tube and metal float. This is suitable for a measure the flow rate of liquid of low to medium temperatures and pressures.

Glass Tube Variable Area Flow Meter Applications:

- Analytical instrumentation

- Industrial processes

- Chemical production

- Pharmaceutical production

- Oil & gas extraction

- Refining processes

- Fuel cell research

- Water treatment systems

Metal Tube Variable Area Flow Meter - Metal tube variable area flow meters are another type thatis suitable for temperatures and pressures beyond the physical and mechanical limits of glass tube versions. They are generally manufactured of stainless steel, aluminum, or brass. The piston position is determined by the mechanical and magnetic followers that can be read from the outside of the tube. They are suitable in situations where applications conditions would damage the glass metering tubes, such as steam applications.

Metal Tube Variable Area Flow Meter Applications:

- Purge liquid or gas metering

- Liquid, gas, or oil flow measurement

- Chemical injection

- Rotating equipment flow measurement

- High-pressure flow meters for offshore oil platforms

For more information about variable area flow meters, contact Thomson Equipment by calling 800-528-8997 or visit their web site at https://teco-inc.com. TECO is a National ABB Rotameter Stocking Distributor and has many of the models you need on their shelves now.

Subscribe to:

Comments (Atom)