|

| ABB Rotameter |

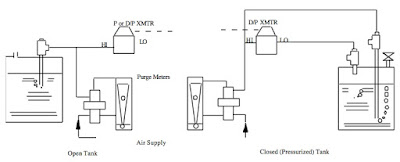

One of the most widely used methods of monitoring/controlling liquid level in a tank is the use of Bubble Tubes with Pressure or Differential Pressure Transmitters. A small, but uninterrupted flow of air or inert gas is forced down through a dip tube which extends to near the bottom of the tank. The back pressure of the introduced gas is a function of the liquid level or head in the tank.

Where Used

- Chemical Companies

- Food & Beverage Companies

How Installed

|

| Bubble Tube Purge for Level Measurement (click for larger view) |

Rotameter Solution

The use of a Purge type Rotameter is the least expensive and most convenient way to set and monitor the flow of air or inert gas into the Bubble Tube.

Method Of Operation

A small, but uninterrupted flow of air (or inert gas such as nitrogen) is easily set and monitored by the use of a Purge Type Rotameter. The flow rate must be low to insure no increase in head back pressure due to pressure drop through the purge piping and dip tube. Conversely the flow cannot be interrupted or the back pressure may decrease below that of the head giving an incorrect level reading and possibly allowing the process liquid to reflux back to the purgemeter and ∆/P Transmitter. Note that controlling the exact flow rate is not critical. The flow rate must be low and uninterrupted. The purge supply gas pressure must exceed the maximum line pressure by about 10psi.

For more information, contact Thompson Equipment at 800-528-8997 or visit http://www.teco-inc.com.

The use of a Purge type Rotameter is the least expensive and most convenient way to set and monitor the flow of air or inert gas into the Bubble Tube.

Method Of Operation

A small, but uninterrupted flow of air (or inert gas such as nitrogen) is easily set and monitored by the use of a Purge Type Rotameter. The flow rate must be low to insure no increase in head back pressure due to pressure drop through the purge piping and dip tube. Conversely the flow cannot be interrupted or the back pressure may decrease below that of the head giving an incorrect level reading and possibly allowing the process liquid to reflux back to the purgemeter and ∆/P Transmitter. Note that controlling the exact flow rate is not critical. The flow rate must be low and uninterrupted. The purge supply gas pressure must exceed the maximum line pressure by about 10psi.

For more information, contact Thompson Equipment at 800-528-8997 or visit http://www.teco-inc.com.