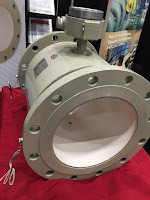

Ultrasonic meters measure flow rate by propagating ultrasound waves into liquid filled pipes and measuring the reflections. There are two technologies to choose from based on the fluid properties; Transit Time and Doppler.

Transit Time - Clean fluids with small amounts of suspended solids or aeration.

For clean fluids with small amounts of suspended solids or aeration, transit time ultrasonic meters provide the best performance and can be used in a wide range of applications for pipes 1/2 inch and larger.

Transit time flow meters have two transducers, which function as both ultrasonic transmitters and receivers. The flow meters operate by alternately transmitting and receiving a frequency modulated burst of ultrasound energy between the two transducers. The burst is first transmitted in the direction of fluid flow and then against fluid flow. Since ultrasound energy in a moving liquid is carried faster when it travels in the direction of fluid flow (downstream) than it does when traveling against fluid flow (upstream), a differential in the times of flight will occur. The ultrasound's time of flight is accurately measured in both directions, and the difference in time of flight is used to determine the velocity of the fluid.

Doppler Flow Meters - Fluids with suspended solids.

For fluids with significant amount of particles or air bubbles, such as slurries, sewage and plastics, Doppler ultrasonic meters provide the best performance.

Each Doppler flow meter utilizes two separate transducer heads. Ultrasonic waves are transmitted from one transducer and reflected by reflectors suspended within the liquid and then recorded by a receiving transducer. If the reflectors are moving within the ultrasound transmission path, ultrasound waves will be reflected at a frequency shifted (Doppler shift) from the transmitted frequency. The difference between the transmitted frequencies and reflected frequencies is directly proportional to the speed of the ultrasonic reflectors.

For more information about clamp-on ultrasonic flow meters, contact Thompson Equipment Company. Call them at 800-528-8997 or visit their web site at https://teco-inc.com.