"Christmas gift suggestions: To your enemy, forgiveness. To an opponent, tolerance. To a friend, your heart. To a customer, service. To all, charity. To every child, a good example. To yourself, respect." — Oren Arnold

Providing educational information on flowmeters, industrial control, process instrumentation, valves, and valve automation. Posts include interesting and unique industrial control applications, new product information, and ways of improving efficiency and saving money through proper maintenance, repair, service, and re-manufacturing.

Courtesy of Thompson Equipment Company | TECO-INC.COM | (504) 833-6381

Fracing vs. Fracking: Winning the Grammar Battle and Losing the Search Engine War

Hydraulic fracturing is the drilling process where layers of bedrock are cracked and spilt using hydraulic fluids to free up and extract oil and natural gas trapped within. TECO is a manufacturer of severe service magnetic flowmeters designed specifically for the hydraulic fracturing industry.

We at TECO believe its important to fully understand an industry's unique processes, challenges, and terminology. By doing so we gain a deep industry knowledge. This knowledge facilitates better communication. Better communication increases understanding and reduces mistakes and errors.

There are very few situations where this isn't the best track to follow. But we found one.

We always tried to do our best by being clear, accurate, and following industry standards. But sometimes you just have to know when to give up. Such is the case with the never-ending "fracing vs. fracking" debate.

This isn't the first essay on the subject, and it won't be the last. It's just that, we here at TECO, have decided to change our online communications approach, based upon some pretty strong data.

While the Oil and Gas industry prefer leaving that lower case "k" out, it's become quite clear that Mr. Google and Mr. Webster decided the "k" needs to be there. And when you're a company making great flow meters, and trying to let people know how good they are, it's makes a world of difference in getting found on the search engines.

It's no secret that Oil and Gas industry people clearly prefer the use of frac or fracing. There are quite a few instances where industry leaders have strongly argued that frac or fracing are the only acceptable spellings. TECO too, decided the industry preferred version was the way to go, and decided that all of our efforts in online marketing and communications would follow suit. We were sure that by sticking to the use of the industry preferred spelling, we'd be in a perfect position to be seen by all the industry professionals searching for "fracing flow meters".

But that didn't happen. Mr. Google wasn't buying it. Search engine results were disappointing. We needed to find out what we were doing wrong.

After careful review of our online content, and use of keywords, we determined it was that lousy lowercase "k". Turns out it makes an insane amount of difference when people use a search engine.

For example, in one test, using a generic keyword tracking tool, we found that the term "fracing" returns a total of 1187 searches, while the term "fracking" returns an astounding 87,836 searches! That means "fracking" is searched for 74 times more than "fracing". You can't ignore that.

Additionally, when you review the Google Trends graph below, you see a vivid illustration of the usage (and trends) for the terms Frac, Frack, Fracing and Fracking (it's pretty clear that Fracking is the winner).

|

| Click for larger view. |

We'll use both. 😀

Clamp-on, Ultrasonic Flow Meters

Ultrasonic meters measure flow rate by propagating ultrasound waves into liquid filled pipes and measuring the reflections. There are two technologies to choose from based on the fluid properties; Transit Time and Doppler.

Transit Time - Clean fluids with small amounts of suspended solids or aeration.

For clean fluids with small amounts of suspended solids or aeration, transit time ultrasonic meters provide the best performance and can be used in a wide range of applications for pipes 1/2 inch and larger.

Transit time flow meters have two transducers, which function as both ultrasonic transmitters and receivers. The flow meters operate by alternately transmitting and receiving a frequency modulated burst of ultrasound energy between the two transducers. The burst is first transmitted in the direction of fluid flow and then against fluid flow. Since ultrasound energy in a moving liquid is carried faster when it travels in the direction of fluid flow (downstream) than it does when traveling against fluid flow (upstream), a differential in the times of flight will occur. The ultrasound's time of flight is accurately measured in both directions, and the difference in time of flight is used to determine the velocity of the fluid.

Doppler Flow Meters - Fluids with suspended solids.

For fluids with significant amount of particles or air bubbles, such as slurries, sewage and plastics, Doppler ultrasonic meters provide the best performance.

Each Doppler flow meter utilizes two separate transducer heads. Ultrasonic waves are transmitted from one transducer and reflected by reflectors suspended within the liquid and then recorded by a receiving transducer. If the reflectors are moving within the ultrasound transmission path, ultrasound waves will be reflected at a frequency shifted (Doppler shift) from the transmitted frequency. The difference between the transmitted frequencies and reflected frequencies is directly proportional to the speed of the ultrasonic reflectors.

For more information about clamp-on ultrasonic flow meters, contact Thompson Equipment Company. Call them at 800-528-8997 or visit their web site at https://teco-inc.com.

Honoring the People Who Protect Our Freedom

Through the observance of Veterans Day we celebrate and honor America's veterans for their patriotism, love of country, willingness to serve, and sacrifice for the common good. We recognize and celebrate those who have chosen to serve in the United States military and take an oath to defend the United States and our Constitution, from all enemies, foreign and domestic.

Veterans Day was originally called Armistice Day because of the November 11 Armistice that ended World War I. In 1954 it was officially changed to Veterans Day to include Veterans of all wars. Thompson Equipment Company thanks our Veterans, past and present, for serving our country and protecting our freedom.

What Are Valve Actuators?

Valve actuators are categorized based upon a number of factors including power source available, torque necessary to operate the valve, installation location, and the need for automatic actuation. Actuators are devices which supply the force and motion to open and close valves. They can be manually, pneumatically, hydraulically, or electrically operated. In common industrial usage, the term actuator generally refers to a device which employs a non-human power source and can respond to a controlling signal.

Electric Actuators

Electric motors permit manual, semi-automatic, and automatic operation of the valve. Motors are used mostly for open-close functions, although they are adaptable to positioning the valve to any point opening as illustrated in Figure 33. The motor is usually a, reversible, high speed type connected through a gear train to reduce the motor speed and thereby increase the torque at the stem. Direction of motor rotation determines direction of disk motion. The electrical actuation can be semi-automatic, as when the motor is started by a control system. A handwheel, which can be engaged to the gear train, provides for manual operating of the valve. Limit switches are normally provided to stop the motor automatically at full open and full closed valve positions. Limit switches are operated either physically by position of the valve or torsionally by torque of the motor.

Pneumatic actuators as illustrated in Figure 34 provide for automatic or semi- automatic valve operation. These actuators translate an air signal into valve stem motion by air pressure acting on a diaphragm or piston connected to the stem. Pneumatic actuators are used in throttle valves for open-close positioning where fast action is required. When air pressure closes the valve and spring action opens the valve, the actuator is termed direct- acting. When air pressure opens the valve and spring action closes the valve, the actuator is termed reverse- acting. Duplex actuators have air supplied to both sides of the diaphragm. The differential pressure across the diaphragm positions the valve stem. Automatic operation is provided when the air signals are automatically controlled by circuitry. Semi-automatic operation is provided by manual switches in the circuitry to the air control valves.

Hydraulic actuators provide for semi-automatic or automatic positioning of the valve, similar to the pneumatic actuators. These actuators use a piston to convert a signal pressure into valve stem motion. Hydraulic fluid is fed to either side of the piston while the other side is drained or bled. Water or oil is used as the hydraulic fluid. Solenoid valves are typically used for automatic control of the hydraulic fluid to direct either opening or closing of the valve. Manual valves can also be used for controlling the hydraulic fluid; thus providing semi-automatic operation.

For more information on valve actuators and valve automation, contact Thompson Equipment Company (TECO) by calling 800-528-8997 of visit the valve automation area of their web site here.

Types of actuators include:

- Manual handwheel or lever

- Electrical motor

- Pneumatic

- Hydraulic

|

| Gear Operator |

Manual Actuators

Manual actuators are capable of placing the valve in any position but do not permit automatic operation. The most common type mechanical actuator is the handwheel. This type includes handwheels fixed to the stem, hammer handwheels, and handwheels connected to the stem through gears.Gear Operators

If additional mechanical advantage is necessary for a manually-operated valve, the valve bonnet is fitted with manually-operated gear heads as illustrated in Figure 32. A special wrench or handwheel attached to the pinion shaft permits one individual to operate the valve when two individuals might be needed without the gear advantage. Because several turns of the pinion are necessary to produce one turn of the valve stem, the operating time of large valves is exceptionally long. The use of portable air motors connected to the pinion shaft decreases the valve operating time.

Electric Actuators

|

| Electric Actuator |

Pneumatic Actuators

|

| Pneumatic Actuator |

Hydraulic Actuators

|

| Hydraulic Actuator |

For more information on valve actuators and valve automation, contact Thompson Equipment Company (TECO) by calling 800-528-8997 of visit the valve automation area of their web site here.

The Top 10 Fluid Flow Measurement Application Questions

|

| Variable area flow meter (ABB) |

|

| Severe service flow meter (TECO) |

- Is the measured process media a liquid or a gas?

- Is the flow measurement occurring in a pipe or in an open channel?

- What is the the flow rate?

- How much does the flow vary?

- If liquid, is it clean or does it contain suspended solids or air bubbles?

- What accuracy is required?

- How much head loss by the flowmeter is permissible?

- Is the flow corrosive or erosive?

- What types of flowmeter technologies can be accommodated in the location?

- What types of post installation service is available in area?

|

| Positive Displacement Meter (Blancett) |

Selecting and configuring a flow measurement device properly, and assuring that installation is done correctly, are necessary tasks to achieving optimal flow meter performance. Reach out to a flow meter specialist with your flow application. By combining your process knowledge with their product application expertise, an effective and long lasting solution will result.

For more information about any flow measurement application, contact Thompson Equipment. The can be reached by calling 800-528-8997 or by visiting https://teco-inc.com.

Flow Measurement for Hydraulic Fracturing and the Production of Shale Gas

|

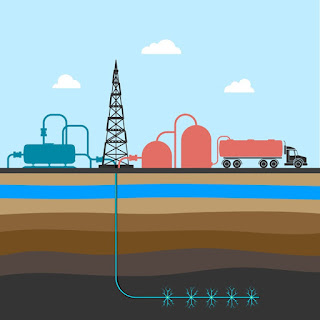

| Figure 1. Illustration of the fracing (fracking) process. (Image courtesy of EPA.gov) |

A “conventional” gas reservoir is produced from sands and carbonates (such as limestone). In the conventional reservoir, the gas is in interconnected pore spaces, much like a kitchen sponge, that allow easier flow to a well. In an "unconventional" gas reservoir, such as shale, the reservoir must be mechanically “stimulated” to create additional permeability and free the gas for collection. Permeability refers to the capacity of a porous, sediment, soil – or rock in this case – to transmit a fluid. Unconventional reservoirs include tight gas (low-porosity sandstones and carbonate reservoirs) and coal bed methane (CBM – gas produced from coal seams).

For shale gas, hydraulic fracturing (known as "fracing" or "fracking") of a reservoir is the preferred stimulation method (figure 1). This typically involves injecting pressurized fluids to stimulate or fracture shale formations and release the natural gas. Sand pumped in with the fluids (often water) helps to keep the fractures open. The type, composition and volume of fluids used depend largely on the geologic structure, formation pressure and the specific geologic formation and target for a well. If water is used as the pressurized fluid, as much as 20 percent can return to the surface via the well (known as flow back). This water can be treated and reused – in fact, reuse of flow back fluids for subsequent hydraulic fracture treatments can significantly reduce the volume of wastewater generated by hydraulic fracturing.

The hydraulic fracturing process was used in conventional limestone and sandstone reservoirs for decades before the onset of the shale revolution. But it was not until the 1970s that significant attempts to apply the technology to gas shale were made, pioneered by DOE research and demonstration project cost-sharing with industry in such ventures as the Eastern Gas Shales Project (1976-92).

Another major technology often employed in producing natural gas from shale is horizontal drilling. The shallow section of shale wells are drilled vertically (much like a traditional conventional gas well). Just above the target depth – the place where the shale gas formation exists – the well deviates and becomes horizontal. At this location, horizontal wells can be oriented in a direction that maximizes the number of natural fractures intersected in the shale. These fractures can provide additional pathways for the gas that is locked away in the shale, once the hydraulic fracturing operation takes place.

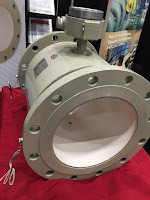

Accurate flow measurement is important in fracking applications and required for reliable data reporting to supervisory agencies. The preferred technology for measuring flow in fracking applications are magnetic flowmeters (magmeters), primarily for their non-obstructive flow path, accuracy and reasonable cost. There are caveats associated with applying magmeters in fracking applications and selection of specialized flow meter components is required. Fracking sand is very erosive and chemicals mixed with the fracking water can be erosive. Any flow meter used in fracking applications must be rugged enough to withstand these harsh conditions.

|

| Flow meter designed for fracking applications (as well as for other abrasive slurries) by TECO. |

An excellent solution that provides all the the virtues of magnetic flowmeters and overcomes performance and longevity issues referred to as "severe service flowmeters" or "slurry flow meters" designed with components matched specifically to withstand the mechanical and chemical abuse they will see. Their modifications include:

- A ceramic sleeved liner made of magnesia partially stabilized zirconia. This ceramic can handle the abrasion and chemical attack with very little degradation.

- Highly polished, ultra-smooth Tungsten electrodes. The Tungsten provides outstanding wear resistance while the high-polish reduces electrical noise introduced in the electrode circuitry.

- Special coatings, or paints, to provide exterior protection.

For more information on fracking (or fracing) magnetic flow meters, contact Thompson Equipment Company (TECO) by calling 800-528-8997 or visit https://teco-inc.com.

Source: How is Shale Gas Produced? https://www.energy.gov/fe/shale-gas-101

Handbook for Variable Area Flowmeters

This “Handbook for Variable Area Flowmeters“, courtesy of ABB and Thompson Equipment, is a practical guide for the user with selection criteria for real applications (see Check List/Parameter Questionnaire), correction factors, Accuracy Classes, corrosion resistance tables and much more. A separate flyer with actual pictures demonstrate the application versatility.

Answers are provided to frequently asked questions about this measurement principle (see Page 20) and we have incorporated a preferential quick ship program for the most popular instrument versions.

We hope that this Handbook provides you with a practical selection guide; naturally our sales team is always ready to provide you with any personal assistance you may require.

Thompson Equipment (TECO)

800-528-8997

https://teco-inc.com

Answers are provided to frequently asked questions about this measurement principle (see Page 20) and we have incorporated a preferential quick ship program for the most popular instrument versions.

We hope that this Handbook provides you with a practical selection guide; naturally our sales team is always ready to provide you with any personal assistance you may require.

Thompson Equipment (TECO)

800-528-8997

https://teco-inc.com

What Are Variable Area Flow Meters?

Variable area flow meters, also referred to as Rotameters, have diverse industrial processing applications that range from simple to sophisticated. The devices are easy to install, require no electrical connection, and provide direct flow rate reading. They provide fail-safe flow rate readings in a wide array of industrial applications.

Developed by German inventor Karl Kueppers in 1908, Rotameters measure the volumetric flow rate of liquids and gases.

Important elements of a variable area flow meter include the tube and the float. Their operation is simple. The tube is fixed vertically and the fluid is fed from the bottom. It travels upward and exits from the top. The float remains at the bottom when no liquid is present and rises upward when fluid enters the tube.

The float inside the tube moves in proportion to the rate of fluid flow and the area between the tube wall and the float. When the float moves upward, the area increases while the differential pressure decreases. A stable position is reached when the upward force exerted by the fluid is equal to the weight of the float. A scale mounted on the tube records the flow rate of the liquid. Usually, the flow can be adjusted manually using a built-in valve.

Variable area flow meters can be categorized by the type of tube they use, which relates to their ability to withstands various pressures, temperatures, process media, and cost. Process connection size and wetted part materials vary as a function the rotameter type and construction.

Plastic Tube Variable Area Flow Meter - For many non-corrosive, low-pressure air, water and gas flow applications. Made of machined acrylic or molded polycarbonate.

Plastic Tube Variable Area Flow Meter Applications:

Glass Tube Variable Area Flow Meter - The basic glass variable area flow meter consists of borosilicate glass tube while the float is made of either glass, plastic, or stainless steel. The most common combination is a glass tube and metal float. This is suitable for a measure the flow rate of liquid of low to medium temperatures and pressures.

Glass Tube Variable Area Flow Meter Applications:

Metal Tube Variable Area Flow Meter - Metal tube variable area flow meters are another type thatis suitable for temperatures and pressures beyond the physical and mechanical limits of glass tube versions. They are generally manufactured of stainless steel, aluminum, or brass. The piston position is determined by the mechanical and magnetic followers that can be read from the outside of the tube. They are suitable in situations where applications conditions would damage the glass metering tubes, such as steam applications.

Metal Tube Variable Area Flow Meter Applications:

Variable Area Flow Meters: An Overview

Developed by German inventor Karl Kueppers in 1908, Rotameters measure the volumetric flow rate of liquids and gases.

Important elements of a variable area flow meter include the tube and the float. Their operation is simple. The tube is fixed vertically and the fluid is fed from the bottom. It travels upward and exits from the top. The float remains at the bottom when no liquid is present and rises upward when fluid enters the tube.

The float inside the tube moves in proportion to the rate of fluid flow and the area between the tube wall and the float. When the float moves upward, the area increases while the differential pressure decreases. A stable position is reached when the upward force exerted by the fluid is equal to the weight of the float. A scale mounted on the tube records the flow rate of the liquid. Usually, the flow can be adjusted manually using a built-in valve.

Types of Variable Area Flow Meters

Variable area flow meters can be categorized by the type of tube they use, which relates to their ability to withstands various pressures, temperatures, process media, and cost. Process connection size and wetted part materials vary as a function the rotameter type and construction.

Plastic Tube Variable Area Flow Meter - For many non-corrosive, low-pressure air, water and gas flow applications. Made of machined acrylic or molded polycarbonate.

Plastic Tube Variable Area Flow Meter Applications:

- Water treatment systems

- Gas analyzers

- Air sampling equipment

- Desalinization equipment

- Medical equipment

- Photo processing equipment

- OEM machines

Glass Tube Variable Area Flow Meter - The basic glass variable area flow meter consists of borosilicate glass tube while the float is made of either glass, plastic, or stainless steel. The most common combination is a glass tube and metal float. This is suitable for a measure the flow rate of liquid of low to medium temperatures and pressures.

Glass Tube Variable Area Flow Meter Applications:

- Analytical instrumentation

- Industrial processes

- Chemical production

- Pharmaceutical production

- Oil & gas extraction

- Refining processes

- Fuel cell research

- Water treatment systems

Metal Tube Variable Area Flow Meter - Metal tube variable area flow meters are another type thatis suitable for temperatures and pressures beyond the physical and mechanical limits of glass tube versions. They are generally manufactured of stainless steel, aluminum, or brass. The piston position is determined by the mechanical and magnetic followers that can be read from the outside of the tube. They are suitable in situations where applications conditions would damage the glass metering tubes, such as steam applications.

Metal Tube Variable Area Flow Meter Applications:

- Purge liquid or gas metering

- Liquid, gas, or oil flow measurement

- Chemical injection

- Rotating equipment flow measurement

- High-pressure flow meters for offshore oil platforms

For more information about variable area flow meters, contact Thomson Equipment by calling 800-528-8997 or visit their web site at https://teco-inc.com. TECO is a National ABB Rotameter Stocking Distributor and has many of the models you need on their shelves now.

New Batch of Severe Service Magmeters for Fracing Service from TECO

For more information about severe service magnetic flowmeters, contact Thompson Equipment Company by calling 800-528-8997 or visit https://teco-inc.com.

A Special Connection Between D-Day and TECO

|

| TECO Headquarters |

Todd Thompson, President of Thompson Equipment, has a very special story to tell on D-Day.

|

| Higgins Boat full of soldiers. |

"My great grandfather Horace Thompson Sr., the father of TECO’s founder, Horace Thompson, Jr., was the head of the US Army Corps of Engineers in New Orleans. He had a need for a vessel that could work on the river side of the Mississippi River levees. His friend Andrew Higgins developed the solution, which was ultimately mass produced in New Orleans and used in WWII as the Higgins Landing Craft. "

|

| Higgins Landing Craft statue given to Horace Thompson by Andrew Higgins. |

Mr. Thompson goes on to say, "Obviously this is a meaningful day for all Americans, but in New Orleans and at TECO, we feel particularly proud of the accomplishments of our forefathers every 6th of June."

A warm "Happy Landings" to all of you from TECO on this very special day.

A warm "Happy Landings" to all of you from TECO on this very special day.

Volumetric Flow, Pressure, Temperature, and Totalizer All-in-One for Compressed Air Systems

The ifm SD ”All-in-one sensor“ compressed air flowmeter integrates a temperature sensor and a pressure sensor, allowing the user to read four process values at once (volumetric flow, pressure, temperature, totalizer = total quantity meter).

The SD’s precise flow monitoring allows for leakage detection and energy cost savings. Thanks to the integrated pressure measurement, both the pressure drop on the polluted filter systems and the compressed air system’s general operating pressure can be optimally monitored.

For more information, contact Thompson Equipment Company. Phone them at 800-528-8997 or visit their website at https://teco-inc.com.

Magnetic Flow Meters: Basic Principles

Magnetic flow meters are used in many industrial applications. The device is preferred due to being cost-effective, providing accurate volumetric measurement, and an obstruction-less pathway for slurries and aggressive chemicals.

The operation of magnetic flow meters is different than other measurement devices. The post will highlight the basic principles of the device and also shed light on pros, cons, and industrial application.

The device creates a magnetic field to channel the flow of fluid through a pipe. As the fluid passes through the magnetic field, a voltage signal is created. The faster the fluid flows through the pipe, the higher the voltage produced by the device.

The voltage is picked up by electrode sensors that are located inside the tube. The signals are then conveyed to an electronic transmitter that processes the signal to determine the velocity of the fluid flow.

Magnetic flow meters can be installed in shorter meter runs since they don’t require much upstream and downstream runs. The volumetric flow meters have little or no moving parts and require less maintenance making them a cost-effective option for many industrial applications.

Magnetic flow meters can be installed in shorter meter runs since they don’t require much upstream and downstream runs. The volumetric flow meters have little or no moving parts and require less maintenance making them a cost-effective option for many industrial applications.

Another benefit of the industrial application of magnetic flow meters is that they have a low-pressure drop. Only a slight pressure drop results depending on the length of the tube. This results in more accurate measurement of the liquid flow velocity.

Magnetic flow devices are based on the principle of a linear relationship between the measuring signal and flow rate. In contrast, most other pressure devices work on the principle of a square law relationship. This results in a higher rangeability and accuracy of the magnetic meters.

An important thing that you should keep in mind is that the magnetic flow meters are susceptible to air bubbles. The device cannot differentiate between the process fluid and entrained air. So, the air bubbles will result in an incorrect reading. Air bubbles will cause the meter to give a high reading.

Another thing to remember is that the pipe should be filled completely with water. An incorrect reading will result if the pipe is not full. A solution for this is to install the sensor about 45 to 130 degree angle.

Since the flow meter is obstruction-less, the device is generally applied to measure the velocity of dirty, sanitary, abrasive, and corrosive liquids.

However, the device cannot be used for measuring velocities of liquids with low electrical conductivity such as boiler feed water, deionized water, and hydrocarbons. In addition, the device can also not measure the velocity of gasses.

Unlike insertion magnetic flow meters, inline flow meters don’t require a straight pipe. Moreover, they are best in assessing liquid with higher flow rates.

Magnetic flow meters are reliable in measuring velocities of conductive fluid. The devices have a wide range of industrial application, particularly in commodity transfer. They provide accurate reading and undergo less wear and tear. They are a reliable and cost-effective option for measuring the fluid flow of all conductive fluids.

The device can be used to accurately measure the fluid flow of untreated sewage water, processed water, and aggressive chemicals in water treatment, mining operations, and pulp and paper industries.

The operation of magnetic flow meters is different than other measurement devices. The post will highlight the basic principles of the device and also shed light on pros, cons, and industrial application.

Basic Principle of Magnetic Flow Meters

Magnetic flow meters are also known as electromagnetic flow meters or mag meters. The principle of magnetic flow meter is based on Faraday’s Law of Electromagnetic induction. The law states that a voltage produced across a conductor as it moves through the magnetic field at right angles is directly proportional to the velocity of that conductor.The device creates a magnetic field to channel the flow of fluid through a pipe. As the fluid passes through the magnetic field, a voltage signal is created. The faster the fluid flows through the pipe, the higher the voltage produced by the device.

The voltage is picked up by electrode sensors that are located inside the tube. The signals are then conveyed to an electronic transmitter that processes the signal to determine the velocity of the fluid flow.

Benefits of Magnetic Flow Meters

Magnetic flow meters can be installed in shorter meter runs since they don’t require much upstream and downstream runs. The volumetric flow meters have little or no moving parts and require less maintenance making them a cost-effective option for many industrial applications.

Magnetic flow meters can be installed in shorter meter runs since they don’t require much upstream and downstream runs. The volumetric flow meters have little or no moving parts and require less maintenance making them a cost-effective option for many industrial applications.Another benefit of the industrial application of magnetic flow meters is that they have a low-pressure drop. Only a slight pressure drop results depending on the length of the tube. This results in more accurate measurement of the liquid flow velocity.

Magnetic flow devices are based on the principle of a linear relationship between the measuring signal and flow rate. In contrast, most other pressure devices work on the principle of a square law relationship. This results in a higher rangeability and accuracy of the magnetic meters.

An important thing that you should keep in mind is that the magnetic flow meters are susceptible to air bubbles. The device cannot differentiate between the process fluid and entrained air. So, the air bubbles will result in an incorrect reading. Air bubbles will cause the meter to give a high reading.

Another thing to remember is that the pipe should be filled completely with water. An incorrect reading will result if the pipe is not full. A solution for this is to install the sensor about 45 to 130 degree angle.

Application of Magnetic Flow Meters

Magnetic flow meters can measure velocities of all conductive liquids including water, slurries, and acids. More specifically, the device can measure velocities of liquids with electrical conductivity greater than 5μS/cm.Since the flow meter is obstruction-less, the device is generally applied to measure the velocity of dirty, sanitary, abrasive, and corrosive liquids.

However, the device cannot be used for measuring velocities of liquids with low electrical conductivity such as boiler feed water, deionized water, and hydrocarbons. In addition, the device can also not measure the velocity of gasses.

Types of Magnetic Flow Meter

You can find three common types of a magnetic flow meter in the market. The devices are suitable for different industrial application.Insertion Magnetic Flow Meter

The insertion magnetic flow meter is best for measuring liquid flow in large pipes. The device is simple to install and deliver accurate measurement across a range of pipe sizes.Inline Magnetic Flow Meter

Inline magnetic flow meter is ideal for situations where high accuracy is necessary. The device is generally used for measuring the liquid flow of slurries, wastewater, food, and pulp.Unlike insertion magnetic flow meters, inline flow meters don’t require a straight pipe. Moreover, they are best in assessing liquid with higher flow rates.

Low-flow Magnetic Meters

Low-flow magnetic meters are great for assessing liquid with low flow rates. They are designed in a way to prevent fouling. Similar to insertion magnetic flow meters, the low-flow meters do not require straight pipe. In addition, the device can be used in situations where little space is available between the elbow and the meter.Magnetic flow meters are reliable in measuring velocities of conductive fluid. The devices have a wide range of industrial application, particularly in commodity transfer. They provide accurate reading and undergo less wear and tear. They are a reliable and cost-effective option for measuring the fluid flow of all conductive fluids.

The device can be used to accurately measure the fluid flow of untreated sewage water, processed water, and aggressive chemicals in water treatment, mining operations, and pulp and paper industries.

For more information on magnetic flow meters, contact Thompson Equipment Company (TECO) by calling 800-528-8997 or by visiting https://teco-inc.com.

Comprehensive Guide for ABB VA Master FAM540 Metal Cone Variable Area Flowmeter

The VA Master FAM540 flowmeter can be utilized for measuring the flow of liquids, steam and gases, especially when aggressive or opaque fluids are to be metered. It is ideal for the chemical, pharmaceutical and food and beverage industries.

The VA Master FAM540 flowmeter can be utilized for measuring the flow of liquids, steam and gases, especially when aggressive or opaque fluids are to be metered. It is ideal for the chemical, pharmaceutical and food and beverage industries.This PDF document is a comprehensive collection of data sheets, commissioning instructions, operating instructions, and a spare parts list for the FAM540.

Document Includes

- Data Sheets (DS_FAM540_EN_D_1)

- Commissioning Instructions (CI_FAM540_EN_B_1)

- Operating Instructions (OI_FAM540_EN_D_1)

- Spare Parts List (SPL_FAM540_EN_C)

Operating Principle Behind the Badger Meter RCT1000 Coriolis Flowmeter

This video explains the operating principle behind the Badger Meter Coriolis flowmeter.

The RCT1000 Coriolis flowmeter gives you the ability to measure mass, volume, density and temperature - providing control options to synchronize precision processes. More than simply a flow meter, the RCT1000 by Badger Meter is capable of controlling process flow by sending commands to other instrumentation, such as valves and pumps.

Thompson Equipment (TECO)

http://www.teco-inc.com

800-528-8997

April 11, 2019 is Global Reman Day - Pass the Word

What is Reman?

Remanufacturing is a comprehensive and rigorous industrial process by which a previously sold, leased, used, worn, or non-functional product or part is returned to “like-new” or “better-than-new” condition, from both a quality and performance perspective, through a controlled, reproducible, and sustainable process.

Remanufacturing is a comprehensive and rigorous industrial process by which a previously sold, leased, used, worn, or non-functional product or part is returned to “like-new” or “better-than-new” condition, from both a quality and performance perspective, through a controlled, reproducible, and sustainable process.Global Reman Day is a day to advance the remanufacturing industry through remanufactured-hosted events and workforce development initiatives. Remanufacturing is good for the environment and the economy. Thompson Equipment (TECO) has been a pioneer in the remanufacturing of process instrumentation and flow meters for decades now, and continues to innovate in these areas.

The positive environmental impact remanufacturing instrumentation has on the on the environment has always been crystal clear to TECO. Ending up in a dumpster is a terrible waste of reusable component parts. With a little effort, experience, and knowledge, a wide variety of used process instrumentation can be brought back to life, arguably better than new. Another benefit is the remanufactured item generally comes with a considerable cost savings over new.

Promotional, educational, and technical events are being held on April 11 all over the world! To find out more about Reman Day, and remanufacturing in general, visit https://remanday.org.

Magnetic Flowmeters Used in Industry

|

| Magnetic flow meter. |

Magnetic flow meters are effective for monitoring the flow rate of fluids that present difficult handling problems, such as corrosive acids, sewage, rock and acid slurries, sand and water slurries, paper pulp stock, rosin size, detergents, bleaches, dyes, emulsions, tomato pulp, milk, soda, and beer. Magnetic flow meters mainly are applicable to liquids that have a conductivity of 0.1 microsiemens per centimeter or greater. They are not applicable to petroleum products or gases.

Measurement Principal

The basis of the magnetic flow meter is Faraday's Law of Electromagnetic Induction. In summary, a voltage induced in a conductor (i.e., the fluid flowing in the conduit) moving in a magnetic field is proportional to the velocity of the conductor. This relationship can be expressed mathematically as follows:

E=C×B×D×v

where:

E = induced voltage

C = constant

B = magnetic flux density

D = diameter of conduit

v = velocity of fluid

In principle, the fluid flowing through the pipe passes through the magnetic field. This action generates a voltage that is linearly proportional to the average velocity in the plane of the electrodes. If the velocity profile changes due to swirl or helical flow patterns, the total measured velocity is unaffected as long as the velocity profile across the pipe is symmetrical. Non-symmetrical flow profiles may cause flow rate measurement errors of several percent.

In operation, the magnetic coils create a magnetic field that passes through the flow tube and into the process fluid. When the conductive fluid flows through the flow meter, a voltage is induced between the electrodes, which are in contact with the process fluid and isolated electrically from the pipe walls by a nonconductive liner to prevent a short circuit in the electrode signal voltage. Grounding is required for magnetic flow meters to shield the relatively low voltage signal that is measured at the electrodes from the relatively high common-mode potentials that may be present in the fluid. If the pipe is conductive and comes in contact with the flow meter, the flow meter should be grounded to the pipe both upstream and downstream of the flow meter. If the pipe is constructed of a nonconductive material, such as plastic, or a conductive material that is insulated from the process fluid, such as plastic-lined steel pipe, grounding rings should be installed in contact with the liquid.

Magnetic flow meters can be used in pipes that range in diameter from 0.25 to 240 cm (0.1 to 96 in.). Magnetic flow meters are available for flow rates in the range of 0.008 liters per minute (L/min) (0.002 gallons per minute [gal/min]) to 570,000 L/min (150,000 gal/min). Since magnetic flow meters do not place an obstruction in the pipe, the devices do not cause a loss in fluid pressure. Also, straight pipe requirements do not apply to this flow monitor device. Magnetic flow meters are insensitive to density and viscosity and can measure flow in both directions. In addition, because they cause no obstructions, magnetic flow meters often are used to measure the flow rate of slurries.

Accuracy

If all components of a magnetic flow metering system are calibrated as a unit, system accuracies of ±0.5 percent of flow rate are possible. However, normal accuracy specifications are ±1.0 percent of flow rate. Higher accuracy systems match the primary flow meter with a transmitter in the factory.

For more information on magnetic flow meters, contact TECO by calling 800-528-8997 or visit their web site at https://teco-inc.com.

Hydraulic Fracturing Terms and Definitions

Hydraulic fracturing is the process of using fluid, sand, chemicals, and gels to create or exploit small fractures in a sub-surface rock layer formations in order to stimulate production from oil and gas wells. This fracturing creates paths and reservoirs which increase the rate at which fluids can be taken from the wells. In some cases, this process can increase production by many hundreds of percent.

Hydraulic fracturing is the process of using fluid, sand, chemicals, and gels to create or exploit small fractures in a sub-surface rock layer formations in order to stimulate production from oil and gas wells. This fracturing creates paths and reservoirs which increase the rate at which fluids can be taken from the wells. In some cases, this process can increase production by many hundreds of percent.Below are common terms and definitions* used in the hydraulic fracturing process:

- Additive Pumps – used to inject liquid additives; different types based on the additive type and additive rate.

- Annulus – Area between two concentric casing strings or tubular strings.

- Bottom Hole Treating Pressure (psi) – pressure being applied to the formation including net pressure.

- Centrifugal Pumps – used on the low pressure equipment to mix and move fluid.

- Clean Volume (gal or bbl) – volume of fluid pumped without proppant.

- Dirty Volume (gal or bbl) – volume of fluid pumped with proppant.

- Flowmeter – used to measure and transmit fluid flow rates; different types depending on application.

- Frac Gradient (psi/ft) – pressure at which fluid will cause the formation rock to part.

- High Pressure Pumps – Positive displacement pumps used for pumping downhole.

- Hydraulic Horsepower (hhp) – horsepower being applied to the formation while pumping .

- Hydrostatic Pressure (psi) – pressure the fluid column exerts on the formation.

- Instantaneous Shut-in Pressure (psi) – a pressure used to calibrate the frac gradient.

- Kick-outs – mechanical or electrical devices that activate at a preset pressure to disengage high pressure pumps.

- Liquid Additive (gal/Mgal) – any liquid chemical added to the fluid system for a specific purpose

- Max Pressure (psi) – the maximum WHTP that will be allowed.

- Net Pressure (psi) – excess pressure over frac pressure required to extend the fracture .

- Perf Friction Pressure (psi) – pressure drop across the perforations.

- Pipe Friction Pressure (psi) – friction pressure of the fluid being pumped down the wellbore.

- Pop-off – a mechanical device activates at a preset pressure to prevent damage to surface and downhole tubular.

- Pressure Transducer – device used to measure and transmit pressure data.

- Proppant – small diameter material used to keep the fracture open.

- Proppant Concentration (lb/gal) – the amount of proppant added to one gal of fluid.

- Shut-in Pressure (psi) – a pressure used to calibrate the frac gradient.

- Solid Additive (lb/Mgal) – a solid chemical added to the fluid system for a specific purpose.

- Treatment Rate (bpm) – the downhole rate that fluid is entering the formation pumping.

- Wellhead Treating Pressure (psi) – the surface pressure at the wellhead during.

Thompson Equipment (TECO) manufactures highly engineered flowmeters designed for optimum performance in fracing applications. Contact TECO to discuss any severe flow measurement application.

TECO

800-528-8997

* from EPA.gov workshop titled "Fracture Design and Stimulation – Monitoring" (DC01:570405.2)

The Role of the High and Low Pressure Ports on a Differential Pressure Transmitter

http://www.teco-inc.com

800-528-8997

Thermo Scientific Ramsey

Thermo Scientific Ramsey manufactures industrial in-motion weighing, monitoring and inspection equipment used for process control and production control in a wide variety of industrial applications. Products include weighbelt feeders, belt scales, metal detectors, sampling systems, level indicators, conveyor safety switches. Below is an embedded copy of the Thermo Scientific / Ramsey Bulk Weighing and Monitoring Catalog. You can download a copy at the TECO website here.

Electromagnetic Flow Metering

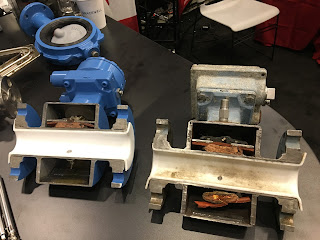

|

| Cutaways of electromagnetic flow meters - one removed from service (right) and one remanufactured (left). |

Electromagnetic flow metering is based on the principles of Michael Faraday's 1832 discovery. When a conductive liquid, such as water, is moved through a magnetic field a voltage is induced in the liquid at right angles to the magnetic field. The size of the voltage is directly proportional to the volume flow rate. This induced voltage is detected by sensors known as electrodes. These electrodes transfer the voltage signal to the processing electronics where it can be converted into a usable industrial standard signal.

It's important that the flow meter tube is non-magnetic, and austenitic stainless steel is the most commonly used material. It's also essential that the flow meter tube has a lining that electrically insulates it from the liquid inside, and provides a non-reactive barrier with any corrosive liquids being measured. Distinguishing between flow induced voltage changes, electrochemical noise, and plant induced noise, is a barrier to accurate electromagnetic flow metering. This can be particularly difficult in dirty and industrial applications. The choice of electromagnetic flowmeters with advanced noise suppression can mitigate unwanted noise and provide extremely high orders of accuracy as a result.

To ensure that your electromagnetic flow meters will be optimized for safety, longevity, and performance, the advice of a qualified flow instrumentation expert should be sought out. That expert will be able to help you with the best selection of the appropriate flow device for your specific application, be it electromagnetic flow meters or another flow technology.

Differential Pressure Flow Metering for the Chemical Processing Industry White Paper

Flow measurement is a critical aspect of plant operation in the Chemical Processing Industry (CPI). Users choosing equipment to meter the flow of liquid or gas processes must consider a wide range of factors to arrive at an optimal solution Experience has shown there are significant differences between meter technologies, with each type of device having its own advantages and disadvantages for processing facilities

Flow measurement is a critical aspect of plant operation in the Chemical Processing Industry (CPI). Users choosing equipment to meter the flow of liquid or gas processes must consider a wide range of factors to arrive at an optimal solution Experience has shown there are significant differences between meter technologies, with each type of device having its own advantages and disadvantages for processing facilitiesCommon Differential Flow Metering Methods:

- Venturi

- Cone Meter

- Wedge Meter

- Averaging Pitot Tube

Badger Meter, a premier manufacturer of industrial flow meters, has authored an excellent white paper explaining the use of differential pressure flow metering in the chemical processing industry. You can get the white paper at this link.

For more information, visit Thompson Equipment Company (TECO) at https://teco-inc.com or call 800-528-8997 for immediate service.

Remanufactured Flowmeters, Instrumentation & Valves

TECO has the experience, trained technicians, and facilities to remanufacture your equipment to meet or exceed all OEM specifications and performance standards. Send us your old flowmeter, process instrument, or valve and we'll send it back to you as good as new.

Thompson Equipment Company

https://teco-inc.com

800-528-8997

Magnetic Flowmeters for Fracing

|

| Fracing illustration (USGS) |

Flow measurement is very important in fracing and requires instrumentation with long life and high accuracy. Frac fluid is a very nasty slurry and it's flow measurement is challenging. Flow instruments are exposed to high pressures, erosive materials and corrosive chemicals.

Frac sand is very erosive and the high pressure and corrosive chemicals complicate things exponentially. Any flowmeter used in fracing applications must not only be rugged enough to withstand these harsh conditions, but the flowmeter must also provide the accuracy required for reliable data reporting to supervisory agencies. Cost-effectively meeting accuracy and longevity requirements for these applications can be frustrating.

Frac sand is very erosive and the high pressure and corrosive chemicals complicate things exponentially. Any flowmeter used in fracing applications must not only be rugged enough to withstand these harsh conditions, but the flowmeter must also provide the accuracy required for reliable data reporting to supervisory agencies. Cost-effectively meeting accuracy and longevity requirements for these applications can be frustrating.Magnetic flowmeters have always appealed to the fracing industry because of their unfettered flow path, availability of sizes and level of accuracy. Their downfall is their longevity. Standard, off-the-shelf magnetic flowmeters don't last in this environment and can't be considered an economically viable choice.

An excellent solution that provides all the the virtues of magnetic flowmeters, and overcomes the longevity and economics issues, are specialized magnetic flowmeters. Referred to as "severe service flowmeters" or "slurry flowmeters", they are designed with components matched specifically to withstand the mechanical and chemical abuse they will see.

Magnetic flowmeters, specialized for fracing, provide all of a "magmeters" desirable features with these critical enhancements:

- A ceramic sleeved liner made of magnesia partially stabilized zirconia. This ceramic can handle the abrasion and chemical attack with very little degradation.

- Highly polished, ultra-smooth Tungsten electrodes. The Tungsten provides outstanding wear resistance while the high-polish reduces electrical noise introduced in the electrode circuitry.

- Special coatings, or paints, to provide exterior protection.

By specifying magnetic flowmeters, specialized for fracing, not only do operators save money through increased uptime and decreased health, safety and environmental risk, but also through reduced costs related to flowmeter purchase and repair.

By specifying magnetic flowmeters, specialized for fracing, not only do operators save money through increased uptime and decreased health, safety and environmental risk, but also through reduced costs related to flowmeter purchase and repair.

For more information on fracing magnetic flowmeters, contact Thompson Equipment Company (TECO) by calling 800-528-8997 or visit https://teco-inc.com.

Magnetic Flow Meters for Abrasive Service

Magnetic flow meters (magmeters) apply Faraday’s Law of Electromagnetic Induction to measure flow. They are specifically designed for conductive fluids like water, acids, caustic liquids, and slurries.

Magnetic flowmeters differ in materials, size, corrosion resistance, pressure and temperature performance. Properly applying magnetic flow meters for abrasive and/or erosive slurry measurement is one of the most challenging applications for plant engineers and maintenance managers to address. The proper combination of design components is critical.

If you have a challenging flow measurement application that involves abrasive or erosive media, contact TECO for assistance. A short conversation with one of our application engineers will save you a great deal of time and money.

Thompson Equipment Company

http://www.teco-inc.com

800-528-8997

Subscribe to:

Comments (Atom)